0.6/1kV 2 Cores - 5 Cores Mica Tape Fire Resistant Power Cable to IEC 60502

CU/MGT/XLPE/LSZH (2 Cores - 5 Cores)

Mica Tape, XLPE Insulated, LSZH Sheathed Cable

Application

These cables are suitable for indoor and outdoor applications, where a high safety against flame is required .

Public address and emergency voice communication system and traffic control centres.

Control and instrumentation service in industrial, commercial and residential buildings.

Such as: Schools&Universities, Hospital, Markets & Malls, Hotels, Theatres, Cinemas, Airports, Underground stations, Tunnels, Recreational

places& Amusement parks, Indoor work places.

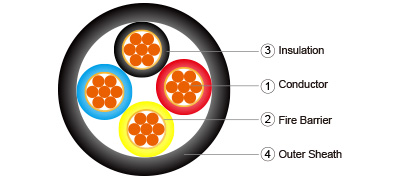

Construction

Conductor: Plain annealed copper, class1 solid or class 2 stranded as per IEC 60228.

Flexible class 5 or tinned conductor could be offer upon request.

Fire Barrier: Mica tape (MGT).

Insulation: Cross-linked polyethlene (XLPE) compound as per IEC 60502-1.

Insulation Colour:

| Number of Cores | Color Code to IEC 60502-1 | Color Code to BS 5467 |

| 2 | Red & Black | Brown & Blue |

| 3 | Red, Yellow and Blue | Brown, Black and Grey |

| 4 | Red, Yellow, Blue and Black | Blue, Brown, Black and Grey |

| 5 | Red, Yellow, Blue, Black and Green / Yellow |

Green / Yellow, Blue, Brown, Black and Grey |

Assembly: Cores cabled together with PP filler and covered with non-woven tape.

Outer Sheath: Low smoke zero halogen (LSZH) compound ST8 (90°C) of IEC 60502-1.

Outer Sheath Colour: Black or other color as per customer request.

Electrical Characteristics

Recommended rated voltages U0

| Highest system voltage (Um) (kV) |

Rated voltage (U0) (kV) | |

| Categories A and B | Category C | |

| 1,2 | 0,6 | 0,6 |

Routine test voltages

| Rated voltage U0 (kV) | 0,6 |

| Test voltage (kV) | 3,5 |

Maximum conductor temperatures for different types of insulating compound

| Maximum conductor temperature (°C) | |

| Normal operation | Short-circuit (5 s maximum duration) |

| 90 | 250 |

Operating Temperature: -15°C to 90°C

Test Voltage: 3.5 kV for 5 minutes

Installation Reference

Min.Bending Radius (mm): 8 x cable overall diameter

Max.Pulling Tension (N/mm2): 50

Reference Standards

Design Specification: IEC60502-1

Conductor: EC60228, BS EN60228

Flame Retardancy: IEC60332-3-22, BS EN60332-3-22

Low Smoke Zero Halogen: IEC61034-2, BS EN61034-2, IEC60754-1, IEC60754-2, BS EN50267-2-1, BS EN50267-2-2

Dimension

2 Cores

| Nominal Conductor Area (mm2) |

No.and Diameter of Wires (mm) |

Thickness of Insulation (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 2x1.5 | 7/0.53 | 0.7 | 1.8 | 11.4 | 144 |

| 2x2.5 | 7/0.67 | 0.7 | 1.8 | 12.2 | 175 |

| 2x4 | 7/0.85 | 0.7 | 1.8 | 13.3 | 222 |

| 2x6 | 7/1.04 | 0.7 | 1.8 | 14.4 | 279 |

| 2x10 | 7/1.35 | 0.7 | 1.8 | 16.3 | 391 |

| 2x16 | 7/1.70 | 0.7 | 1.8 | 18.4 | 545 |

| 2x25 | 7/2.14 | 0.9 | 1.8 | 21.8 | 798 |

| 2x35 | 7/2.52 | 0.9 | 1.8 | 24.1 | 1039 |

| 2x50 | 19/1.78 | 1 | 1.8 | 27.2 | 1352 |

| 2x70 | 19/2.14 | 1.1 | 1.9 | 31.4 | 1884 |

| 2x95 | 19/2.52 | 1.1 | 2 | 35.4 | 2524 |

| 2x120 | 37/2.03 | 1.2 | 2.2 | 39.4 | 3165 |

| 2x150 | 37/2.25 | 1.4 | 2.3 | 43.5 | 3860 |

| 2x185 | 37/2.52 | 1.6 | 2.5 | 48.5 | 4818 |

| 2x240 | 61/2.25 | 1.7 | 2.7 | 54.5 | 6238 |

| 2x300 | 61/2.52 | 1.8 | 2.9 | 60.2 | 7746 |

| 2X400 | 61/2.85 | 2 | 3.1 | 67.3 | 9817 |

| 2X500 | 61/3.20 | 2.2 | 3.3 | 74.8 | 12274 |

| 2X630 | 127/2.52 | 2.4 | 3.6 | 84.1 | 15726 |

| 2X800 | 127/2.85 | 2.6 | 4 | 94.3 | 20011 |

| 2x1000 | 127/3.20 | 2.8 | 4.3 | 104.8 | 25047 |

3 Cores

| Nominal Conductor Area (mm2) |

No.and Diameter of Wires (mm) |

Thickness of Insulation (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 3x1.5 | 7/0.53 | 0.7 | 1.8 | 12 | 178 |

| 3x2.5 | 7/0.67 | 0.7 | 1.8 | 12.9 | 221 |

| 3x4 | 7/0.85 | 0.7 | 1.8 | 14 | 287 |

| 3x6 | 7/1.04 | 0.7 | 1.8 | 15.3 | 369 |

| 3x10 | 7/1.35 | 0.7 | 1.8 | 17.3 | 529 |

| 3x16 | 7/1.70 | 0.7 | 1.8 | 19.5 | 752 |

| 3x25 | 7/2.14 | 0.9 | 1.8 | 23.2 | 1119 |

| 3x35 | 7/2.52 | 0.9 | 1.8 | 25.7 | 1470 |

| 3x50 | 19/1.78 | 1 | 1.8 | 29 | 1929 |

| 3x70 | 19/2.14 | 1.1 | 2 | 33.7 | 2721 |

| 3x95 | 19/2.52 | 1.1 | 2.1 | 38 | 3660 |

| 3x120 | 37/2.03 | 1.2 | 2.3 | 42.3 | 4591 |

| 3x150 | 37/2.25 | 1.4 | 2.4 | 46.7 | 5609 |

| 3x185 | 37/2.52 | 1.6 | 2.6 | 52 | 7004 |

| 3x240 | 61/2.25 | 1.7 | 2.8 | 58.5 | 9085 |

| 3x300 | 61/2.52 | 1.8 | 3 | 64.5 | 11292 |

| 3x400 | 61/2.85 | 2 | 3.3 | 72.4 | 14368 |

| 3x500 | 61/3.20 | 2.2 | 3.5 | 80.5 | 17982 |

| 3X630 | 127/2.52 | 2.4 | 3.8 | 90.4 | 23055 |

| 3X800 | 127/2.85 | 2.6 | 4.2 | 101.3 | 29338 |

| 3x1000 | 127/3.20 | 2.8 | 4.6 | 112.8 | 36808 |

4 Cores

| Nominal Conductor Area (mm2) |

No.and Diameter of Wires (mm) |

Thickness of Insulation (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 4x1.5 | 7/0.53 | 0.7 | 1.8 | 13 | 215 |

| 4x2.5 | 7/0.67 | 0.7 | 1.8 | 14 | 271 |

| 4x4 | 7/0.85 | 0.7 | 1.8 | 15.3 | 356 |

| 4x6 | 7/1.04 | 0.7 | 1.8 | 16.7 | 463 |

| 4x10 | 7/1.35 | 0.7 | 1.8 | 18.9 | 674 |

| 4x16 | 7/1.70 | 0.7 | 1.8 | 21.5 | 966 |

| 4x25 | 7/2.14 | 0.9 | 1.8 | 25.6 | 1449 |

| 4x35 | 7/2.52 | 0.9 | 1.8 | 28.4 | 1912 |

| 4x50 | 19/1.78 | 1 | 1.9 | 32.3 | 2534 |

| 4x70 | 19/2.14 | 1.1 | 2.1 | 37.5 | 3576 |

| 4x95 | 19/2.52 | 1.1 | 2.3 | 42.5 | 4840 |

| 4x120 | 37/2.03 | 1.2 | 2.4 | 47.1 | 6043 |

| 4x150 | 37/2.25 | 1.4 | 2.6 | 52.2 | 7413 |

| 4x185 | 37/2.52 | 1.6 | 2.8 | 58.1 | 9255 |

| 4x240 | 61/2.25 | 1.7 | 3 | 65.3 | 12006 |

| 4x300 | 61/2.52 | 1.8 | 3.2 | 72 | 14925 |

| 4x400 | 61/2.85 | 2 | 3.5 | 80.7 | 18987 |

| 4x500 | 61/3.20 | 2.2 | 3.8 | 89.9 | 23815 |

| 4X630 | 127/2.52 | 2.4 | 4.2 | 101.2 | 30581 |

| 4X800 | 127/2.85 | 2.6 | 4.6 | 113.4 | 38896 |

| 4x1000 | 127/3.20 | 2.8 | 5 | 126.1 | 48783 |

5 Cores

| Nominal Conductor Area (mm2) |

No.and Diameter of Wires (mm) |

Thickness of Insulation (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 5x1.5 | 7/0.53 | 0.7 | 1.8 | 14.1 | 253 |

| 5x2.5 | 7/0.67 | 0.7 | 1.8 | 15.2 | 322 |

| 5x4 | 7/0.85 | 0.7 | 1.8 | 16.7 | 427 |

| 5x6 | 7/1.04 | 0.7 | 1.8 | 18.2 | 559 |

| 5x10 | 7/1.35 | 0.7 | 1.8 | 20.7 | 820 |

| 5x16 | 7/1.70 | 0.7 | 1.8 | 23.6 | 1182 |

| 5x25 | 7/2.14 | 0.9 | 1.8 | 28.2 | 1780 |

| 5x35 | 7/2.52 | 0.9 | 1.9 | 31.5 | 2372 |

| 5x50 | 19/1.78 | 1 | 2.1 | 36.1 | 3163 |

| 5x70 | 19/2.14 | 1.1 | 2.3 | 41.9 | 4460 |

| 5x95 | 19/2.52 | 1.1 | 2.4 | 47.2 | 6009 |

| 5x120 | 37/2.03 | 1.2 | 2.6 | 52.5 | 7532 |

| 5x150 | 37/2.25 | 1.4 | 2.8 | 58.1 | 9235 |

| 5x185 | 37/2.52 | 1.6 | 3 | 64.7 | 11526 |

| 5x240 | 61/2.25 | 1.7 | 3.3 | 72.9 | 14988 |

| 5x300 | 61/2.52 | 1.8 | 3.5 | 80.4 | 18625 |

| 5x400 | 61/2.85 | 2 | 3.8 | 90.1 | 23683 |

| 5x500 | 61/3.20 | 2.2 | 4.2 | 100.5 | 29745 |

| 5X630 | 127/2.52 | 2.4 | 4.6 | 113 | 38172 |

| 5X800 | 127/2.85 | 2.6 | 5 | 126.5 | 48530 |

| 5x1000 | 127/3.20 | 2.8 | 5.5 | 140.9 | 60916 |