Application

Suitable for connecting instruments and control systems for analogue or digital signal transmission. Recommended for direct burial, especially in presence of oil and aggressive chemical substances

Construction

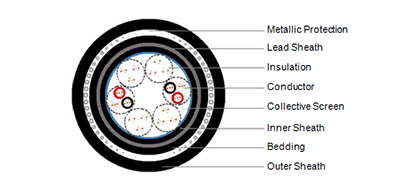

| Lead Sheath | ||

| Insulation | ||

| Conductor | ||

| Collective Screen | ||

| Inner Sheath | ||

| Bedding | ||

| Outer Sheath | ||

| Conductor: | Solid, stranded or flexible plain or metal coated copper in accordance with class1, 2 or 5 of | |

| HD383 in the range of 0.5mm2 to 1.5mm2. | ||

| Insulation: | PVC or XLPE to EN 50290. Suitable alternative materials are under consideration. |

Triple Identification: Black&White&Red color with number on the cores for multi triples, start with 1 in the centre.

| Wrapping: | At least 1 layer of plastic tape. |

| Collective Screen: | Aluminimum foil tape over a tinned copper drain wire. |

| Inner Sheath: | Polyvinyl chloride PVC, to EN 50290-2-22. |

| Lead Sheath: | Lead sheath comply with EN 50307. |

| Bedding: | Polyvinyl chloride PVC, to EN 50290-2-22. |

| Metallic Protection: | Round galvanised steel wires armour. |

| Outer Sheath: | Polyvinyl chloride PVC, to EN 50290-2-22. |

Electrical data at 20°C

Character |

Unit | Values | |||||

| Conductor size | nom. | mm² | 0.5 | 0.75 | 1.0 | 1.5 | |

| Conductor resistance | max. | Ω/km | 36.7 | 25.0 | 18.5 | 12.3 | |

| Insulation resistance | |||||||

| PVC Insulation | min. | MΩ x km | 100 | ||||

| PE/XLPE Insulaiton | min. | MΩ x km | 5000 | ||||

| L/R (ratio) | max. | µH/Ω | 25 | 40 | |||

| Inductance | max. | mH/km | 1 | ||||

| Mutual capacitance | |||||||

| PVC Insulation | max. | nF/m | 150 | 160 | |||

| PE/XLPE Insulation | max. | nF/m | 75 | 85 | |||

| Capacitance unbalance | max. | pF/500 m | 500 | ||||

| Test voltage | V | 1500 | |||||

| Operating voltage U0 / U | max. | V | 300 | ||||