| Standards: | JISC 3410-1999 IEC 60332-1 IEC 60332-3 Cat.A(for FA-type) |

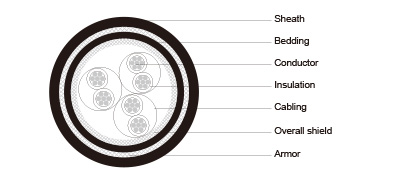

CABLE CONSTRUCTION

| Conductor | TT TTP | Tinned annealed stranded copper (TTY-type) Tinned annealed stranded copper (TTPY-type), class 2 according to IEC 60228 |

| Insulation | 60°C PVC(TTY-type)/ 85°C EPR(TTPY-type) as per JIS C 3401 | |

| Twisting | Two Insulated cores shall be twisted together to form a pair | |

| Cabling | Twisted pairs shall be cabled. Flame retardant & non-hygroscopic fillers may be used | |

| Overall shield | S | Tinned copper wire braid |

| Bedding | Y | PVC as per JIS C 3401 |

| Armor | C | Galvanized steel wire braid |

| Sheath | Y | PVC as per JIS C 3401 |

| Core identification | Printed pair number and Alphabet letter on the white insulation. ex) 4P : (1A, 1B), (2A, 2B), (3A, 3B), (4A, 4B) - 1T, 1Q cable shall be identified by the black number on the white insulation | |

| Outer sheath color | Black |

Cable Parameter

(FA-) TTYS,TTPYS

| No. of pair, Triad or Quad | Conductor | Thick. of insulation | Dia. of shield wire | Thick. of bedding | (FA-) TTYS,TTPYS | ||||

| Size | Construction | O.D | Nom. overall dia | Tolerance | Cable Weight | ||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 1 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 8.8 | 0.4 | 120 |

| 1T | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 9.3 | 0.4 | 140 |

| 1Q | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 10 | 0.5 | 160 |

| 2 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.2 | 13 | 0.6 | 200 |

| 4 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.3 | 15 | 0.7 | 300 |

| 7 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.4 | 17.7 | 0.8 | 420 |

| 10 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.6 | 22.8 | 1.0 | 640 |

| 14 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.6 | 24.4 | 1.0 | 770 |

| 19 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.8 | 27.5 | 1.2 | 970 |

| 24 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.2 | 2 | 33.1 | 1.4 | 1290 |

| 30 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.1 | 35.5 | 1.5 | 1620 |

| 37 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.2 | 38.4 | 1.6 | 1890 |

| 48 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.4 | 44.3 | 1.7 | 2420 |

(FA-) TTYCS,TTPYCS

| No. of pair, Triad or Quad | Conductor | Thick. of insulation | Dia. of shield wire | Thick. of bedding | Dia. of steel wire | (FA-) TTYCS,TTPYCS | ||||

| Size | Construction | O.D | Nom. overall dia | Tolerance | Cable Weight | |||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 1 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 0.3 | 10.1 | 0.4 | 180 |

| 1T | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 0.3 | 10.6 | 0.4 | 205 |

| 1Q | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 0.3 | 11.3 | 0.5 | 230 |

| 2 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.2 | 0.3 | 14.6 | 0.7 | 230 |

| 4 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.3 | 0.3 | 16.3 | 0.7 | 405 |

| 7 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.4 | 0.3 | 19 | 0.7 | 545 |

| 10 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.6 | 0.3 | 24.1 | 1 | 800 |

| 14 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.6 | 0.3 | 25.7 | 1 | 935 |

| 19 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.8 | 0.3 | 28.8 | 1.2 | 1160 |

| 24 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.2 | 2 | 0.4 | 34.9 | 1.4 | 1600 |

| 30 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.1 | 0.4 | 37.3 | 1.5 | 1950 |

| 37 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.2 | 0.4 | 40.2 | 1.6 | 2250 |

| 48 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.4 | 0.4 | 46.1 | 1.7 | 2830 |

(FA-) TTYCYS,TTPYCYS

| No. of pair, Triad or Quad | Conductor | Thick. of insulation | Dia. of shield wire | Thick. of bedding | Dia. of steel wire | Thick. of covering | (FA-) TTYCYS,TTPYCYS | ||||

| Size | Construction | O.D | Nom. overall dia | Tolerance | Cable Weight | ||||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 1 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 0.3 | 0.9 | 12.1 | 0.5 | 230 |

| 1T | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 0.3 | 0.9 | 12.6 | 0.5 | 255 |

| 1Q | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.14 | 1.1 | 0.3 | 0.9 | 13.3 | 0.5 | 285 |

| 2 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.2 | 0.3 | 1 | 16.7 | 0.7 | 285 |

| 4 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.3 | 0.3 | 1 | 18.5 | 0.7 | 490 |

| 7 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.16 | 1.4 | 0.3 | 1.1 | 21.4 | 0.9 | 650 |

| 10 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.6 | 0.3 | 1.2 | 26.7 | 1.1 | 945 |

| 14 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.6 | 0.3 | 1.2 | 28.3 | 1.1 | 1090 |

| 19 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.18 | 1.8 | 0.3 | 1.3 | 31.6 | 1.3 | 1340 |

| 24 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.2 | 2 | 0.4 | 1.5 | 38.3 | 1.5 | 1860 |

| 30 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.1 | 0.4 | 1.5 | 40.7 | 1.6 | 2230 |

| 37 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.2 | 0.4 | 1.6 | 43.8 | 1.7 | 2570 |

| 48 | 0.75 | 7/0.37 | 1.1 | 0.7 | 0.26 | 2.4 | 0.4 | 1.8 | 50.1 | 1.8 | 324 |