FR 200P 1M2XH-R (CU/MGT+XLPE/LSZH 600/1000V Class 2)

FR 200P1M2XHAH-R (CU/MGT+XLPE/LSZH/SWA/LSZH 600/1000V Class 2)

| Application: |

This cable is designed for areas where the integrity of the electrical properties circuit is critical in maintaining power supply. Applications can be found in emergency lightings, control and power circuits, power stations, fire alarm systems, underground tunnels, communications systems, sewage treatment plants, lifts, escalators, and high-rise buildings. |

| STANDARDS: |

Basic design to IEC 60502-1/BS 7846 |

FIRE PERFORMANCE

|

Circuit Integrity |

IEC 60331-21; BS 6387 CWZ; DIN VDE 0472-814(FE180); CEI 20-36/2-1; SS229-1; NBN C 30-004 (cat. F3); NF C32-070-2.3(CR1); BS 7846-(F2) |

|

System circuit integrity |

DIN 4102-12, E30 depending on lay system |

|

Flame Retardance (Single Vertical Wire Test) |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

|

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

|

Halogen Free |

IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

|

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

|

Minimum Smoke Emission |

IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

|

No Toxic gases |

NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

600/1000V

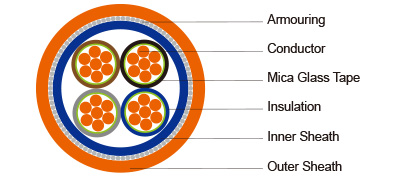

CABLE CONSTRUCTION

- Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

2/3:Insulation: Mica glass tape covered by extruded cross-linked XLPE compound

Cabling: The cores are cabled together in concentric layers with suitable non-hygroscopic fillers.

- Inner Sheath(optional): Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1

- Armouring(optional): Galvanized steel wire armour

- Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH

compound type SW2-SW4 as per BS 7655-2.6 can be offered.)

COLOUR CODE

Insulation Colour

2 - Core: (Brown & Blue)

3 - Core: (Brown, Black & Grey)

4 - Core: (Brown, Black, Grey & Blue)

Sheath Colour

Orange (other colors upon request)

Physical AND THERMAL PROPERTIES

Temperature range during operation (fixed state): -30°C – +90°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 8 x Overall Diameter (unarmoured cable)

10 x Overall Diameter (armoured cable)

Electrical PROPERTIES

|

Dielectric test: |

3500 V r.m.s. x 5' (core/core) |

|

Insulation resistance |

1000 MΩ x km (at 20°C) |

|

Short circuit temperature |

250°C |

CONSTRUCTION PARAMETERS

|

Conductor |

FR 1M2XH-R |

FR 1M2XHAH-R |

||||||

|

No. of Core X Cross Section |

No./ Nominal Diameter of Strands |

Dia. of Conductor |

Nominal Insulation Thickness |

Unarmoured Cable |

Armoured Cable |

|||

|

Nominal Overall Diameter |

Approx. Weight |

Nominal Overall Diameter |

Approx. Weight |

|||||

|

No*mm2 |

No./mm |

mm |

mm |

mm |

kg/km |

mm |

kg/km |

|

|

2 Core |

||||||||

|

1.5 |

7/0.53 |

1.59 |

0.7 |

12.2 |

150 |

15.3 |

390 |

|

|

2.5 |

7/0.67 |

2.01 |

0.7 |

12.6 |

180 |

16.5 |

450 |

|

|

4 |

7/0.85 |

2.55 |

0.7 |

14.7 |

250 |

17.6 |

525 |

|

|

6 |

7/1.04 |

3.12 |

0.7 |

16.2 |

290 |

18.8 |

620 |

|

|

10 |

7/1.35 |

4.05 |

0.7 |

17.1 |

450 |

21 |

800 |

|

|

16 |

7/1.70 |

5.1 |

0.7 |

19.2 |

550 |

23 |

1100 |

|

|

25 |

7/2.14 |

6.42 |

0.9 |

20 |

680 |

27 |

1480 |

|

|

35 |

19/1.53 |

7.65 |

0.9 |

22 |

940 |

30 |

2000 |

|

|

50 |

19/1.78 |

8.9 |

1 |

24 |

1250 |

33 |

2450 |

|

|

70 |

19/2.14 |

10.7 |

1.1 |

27 |

1700 |

37 |

3200 |

|

|

95 |

19/2.52 |

12.6 |

1.1 |

31 |

2300 |

42 |

4350 |

|

|

120 |

37/2.03 |

14.21 |

1.2 |

36 |

3150 |

48 |

6500 |

|

|

3-Core |

||||||||

|

1.5 |

7/0.53 |

1.59 |

0.7 |

12.3 |

170 |

16.5 |

420 |

|

|

2.5 |

7/0.67 |

2.01 |

0.7 |

13.8 |

200 |

17 |

500 |

|

|

4 |

7/0.85 |

2.55 |

0.7 |

15.2 |

300 |

18.5 |

600 |

|

|

6 |

7/1.04 |

3.12 |

0.7 |

16.8 |

380 |

19.8 |

785 |

|

|

10 |

7/1.35 |

4.05 |

0.7 |

18 |

550 |

22.6 |

1030 |

|

|

16 |

1/1.70 |

5.1 |

0.7 |

21 |

760 |

25 |

1370 |

|

|

25 |

7/2.14 |

6.42 |

0.9 |

22 |

960 |

29 |

1900 |

|

|

35 |

19/1.53 |

7.65 |

0.9 |

24 |

1300 |

32 |

2300 |

|

|

50 |

19/1.78 |

8.9 |

1 |

28 |

1700 |

35 |

2900 |

|

|

70 |

19/2.14 |

10.7 |

1.1 |

31 |

2400 |

40 |

4000 |

|

|

95 |

19/2.52 |

12.6 |

1.1 |

36 |

3250 |

45 |

5400 |

|

|

120 |

37/2.03 |

14.21 |

1.2 |

38 |

4000 |

49 |

6450 |

|

|

150 |

37/2.25 |

15.75 |

1.4 |

42 |

5000 |

55 |

8200 |

|

|

185 |

37/2.52 |

17.64 |

1.6 |

47 |

6100 |

60 |

9800 |

|

|

240 |

61/2.25 |

20.25 |

1.7 |

52 |

8000 |

68 |

12300 |

|

|

300 |

61/2.52 |

22.68 |

1.8 |

59 |

9850 |

74 |

14800 |

|

|

400 |

61/2.85 |

25.65 |

2 |

63 |

13000 |

83 |

17600 |

|

|

4-Core |

||||||||

|

1.5 |

7/0.53 |

1.59 |

0.7 |

14.3 |

210 |

16 |

475 |

|

|

2.5 |

7/0.67 |

2.01 |

0.7 |

15.2 |

270 |

17.8 |

570 |

|

|

4 |

7/0.85 |

2.55 |

0.7 |

17.2 |

380 |

19.8 |

690 |

|

|

6 |

7/1.04 |

3.12 |

0.7 |

19 |

440 |

21 |

940 |

|

|

10 |

7/1.35 |

4.05 |

0.7 |

20.6 |

670 |

23.3 |

1200 |

|

|

16 |

1/1.70 |

5.1 |

0.7 |

23.6 |

820 |

26.5 |

1400 |

|

|

25 |

7/2.14 |

6.42 |

0.9 |

26 |

1320 |

30.5 |

2400 |

|

|

35 |

19/1.53 |

7.65 |

0.9 |

29 |

1730 |

34 |

2800 |

|

|

50 |

19/1.78 |

8.9 |

1 |

32 |

2300 |

38 |

3500 |

|

|

70 |

19/2.14 |

10.7 |

1.1 |

38 |

3180 |

44 |

5300 |

|

|

95 |

19/2.52 |

12.6 |

1.1 |

41.9 |

4370 |

48.5 |

6700 |

|

|

120 |

37/2.03 |

14.21 |

1.2 |

44 |

5400 |

54 |

8500 |

|

|

150 |

37/2.25 |

15.75 |

1.4 |

50.8 |

6500 |

59 |

10000 |

|

|

185 |

37/2.52 |

17.64 |

1.6 |

55 |

8200 |

64.5 |

12200 |

|

|

240 |

61/2.25 |

20.25 |

1.7 |

60.5 |

10600 |

74 |

15400 |

|

|

300 |

61/2.52 |

22.68 |

1.8 |

68.5 |

13200 |

82 |

19500 |

|

|

400 |

61/2.85 |

25.65 |

2 |

76 |

17000 |

92 |

25500 |

|

Electrical PROPERTIES

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

FR 1M2XH-R

Current-Carrying Capacities (Amp)

|

Nominal Cross Section Area |

Reference Method 4 (enclosed in an conduit insulated wall etc) |

Reference Method 3 (enclosed in conduit on a wall or ceiling, or in trunking) |

Reference Method 1 (clipped direct) |

Reference Method 11 (on a perforated cable tray), or Reference Method |

|||

|

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

mm2 |

A |

A |

A |

A |

A |

A |

A |

|

1.5 |

16.5 |

22 |

19.5 |

24 |

22 |

26 |

23 |

|

2.5 |

22 |

30 |

26 |

33 |

30 |

36 |

32 |

|

4 |

30 |

40 |

35 |

45 |

40 |

49 |

42 |

|

6 |

38 |

51 |

44 |

58 |

52 |

63 |

54 |

|

10 |

51 |

69 |

60 |

80 |

71 |

86 |

75 |

|

16 |

68 |

91 |

80 |

107 |

96 |

115 |

100 |

|

25 |

89 |

119 |

105 |

138 |

119 |

149 |

127 |

|

35 |

109 |

146 |

128 |

171 |

147 |

185 |

158 |

|

50 |

130 |

175 |

154 |

209 |

179 |

225 |

192 |

|

70 |

164 |

221 |

194 |

269 |

229 |

289 |

246 |

|

95 |

197 |

265 |

233 |

328 |

278 |

352 |

298 |

|

120 |

227 |

305 |

268 |

382 |

322 |

410 |

346 |

|

150 |

259 |

334 |

300 |

441 |

371 |

473 |

399 |

|

185 |

295 |

384 |

340 |

506 |

424 |

542 |

456 |

|

240 |

346 |

459 |

398 |

599 |

500 |

641 |

538 |

|

300 |

396 |

532 |

455 |

693 |

576 |

741 |

621 |

|

400 |

- |

625 |

536 |

803 |

667 |

865 |

741 |

Voltage Drop (Per Amp Per Meter)

|

Nominal Cross Section Area |

2-core cable d.c. |

2-core cable single-phase a.c |

3-core or 4-core cable 3-phase a.c. |

||||

|

1 |

2 |

3 |

4 |

||||

|

mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

||||

|

1.5 |

31 |

31 |

27 |

||||

|

2.5 |

19 |

19 |

16 |

||||

|

4 |

12 |

12 |

10 |

||||

|

6 |

7.9 |

7.9 |

6.8 |

||||

|

10 |

4.7 |

4.7 |

4 |

||||

|

16 |

2.9 |

2.9 |

2.5 |

||||

|

|

|

r |

x |

z |

r |

x |

z |

|

25 |

1.85 |

1.85 |

0.16 |

1.9 |

1.6 |

0.14 |

1.65 |

|

35 |

1.35 |

1.35 |

0.155 |

1.35 |

1.15 |

0.135 |

1.15 |

|

50 |

0.98 |

0.99 |

0.155 |

1 |

0.86 |

0.135 |

0.87 |

|

70 |

0.67 |

0.67 |

0.15 |

0.69 |

0.59 |

0.13 |

0.6 |

|

95 |

0.49 |

0.5 |

0.15 |

0.52 |

0.43 |

0.13 |

0.45 |

|

120 |

0.39 |

0.4 |

0.145 |

0.42 |

0.34 |

0.13 |

0.37 |

|

150 |

0.31 |

0.32 |

0.145 |

0.35 |

0.28 |

0.125 |

0.3 |

|

185 |

0.25 |

0.26 |

0.145 |

0.29 |

0.22 |

0.125 |

0.26 |

|

240 |

0.195 |

0.2 |

0.14 |

0.24 |

0.175 |

0.125 |

0.21 |

|

300 |

0.155 |

0.16 |

0.14 |

0.21 |

0.14 |

0.12 |

0.185 |

|

400 |

0.12 |

0.13 |

0.14 |

0.19 |

0.115 |

0.12 |

0.165 |

FR400 1M2XHAH-R

Current-Carrying Capacities (Amp)

|

Nominal Cross Section Area |

Reference Method 1 (clipped direct) |

Reference Method 11 (on a perforated cable tray), or Reference Method |

In single-way ducts |

Laid direct in ground |

||||

|

one 2-core cable single phase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core or 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core or 4-core cable 3-phase a.c. |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

mm2 |

A |

A |

A |

A |

A |

A |

A |

A |

|

1.5 |

27 |

23 |

29 |

25 |

- |

23 |

- |

28 |

|

2.5 |

36 |

31 |

39 |

33 |

- |

30 |

- |

36 |

|

4 |

49 |

42 |

52 |

44 |

- |

40 |

- |

48 |

|

6 |

62 |

53 |

66 |

56 |

- |

50 |

- |

60 |

|

10 |

85 |

73 |

90 |

78 |

- |

65 |

- |

80 |

|

16 |

110 |

94 |

115 |

99 |

115 |

94 |

140 |

115 |

|

25 |

146 |

124 |

152 |

131 |

145 |

125 |

180 |

150 |

|

35 |

180 |

154 |

188 |

162 |

175 |

150 |

215 |

180 |

|

50 |

219 |

187 |

228 |

197 |

210 |

175 |

255 |

215 |

|

70 |

279 |

238 |

291 |

251 |

260 |

215 |

315 |

265 |

|

95 |

338 |

289 |

354 |

304 |

310 |

260 |

380 |

315 |

|

120 |

392 |

335 |

410 |

353 |

355 |

300 |

430 |

360 |

|

150 |

451 |

386 |

472 |

406 |

400 |

335 |

480 |

405 |

|

185 |

515 |

441 |

539 |

463 |

455 |

380 |

540 |

460 |

|

240 |

607 |

520 |

636 |

546 |

520 |

440 |

630 |

530 |

|

300 |

698 |

599 |

732 |

628 |

590 |

495 |

700 |

590 |

|

400 |

787 |

673 |

847 |

728 |

660 |

560 |

790 |

670 |

Voltage Drop (Per Amp Per Meter)

|

Nominal Cross Section Area |

2-core cable d.c. |

2 cables, single-phase a.c. |

3 or 4 cables, 3-phase a.c. |

2 cables, single- phase a.c. In ducts or in ground |

3 or 4 cables, 3-phase a.c. In ducts or in ground |

||||

|

1 |

2 |

3 |

4 |

5 |

6 |

||||

|

mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

||||

|

1.5 |

31 |

31 |

27 |

31 |

25 |

||||

|

2.5 |

19 |

19 |

16 |

19 |

15 |

||||

|

4 |

12 |

12 |

10 |

12 |

9.7 |

||||

|

6 |

7.9 |

7.9 |

6.8 |

7.9 |

6.5 |

||||

|

10 |

4.7 |

4.7 |

4 |

4.7 |

3.9 |

||||

|

16 |

2.9 |

2.9 |

2.5 |

2.9 |

2.6 |

||||

|

|

|

r |

x |

z |

r |

x |

z |

|

|

|

25 |

1.85 |

1.35 |

0.16 |

1.9 |

1.6 |

0.14 |

1.65 |

1.9 |

1.6 |

|

35 |

1.35 |

1.35 |

0.155 |

1.35 |

1.15 |

0.135 |

1.15 |

1.35 |

1.2 |

|

50 |

0.98 |

0.99 |

0.155 |

1 |

0.86 |

0.135 |

0.87 |

1 |

0.87 |

|

70 |

0.67 |

0.67 |

0.15 |

0.69 |

0.59 |

0.13 |

0.6 |

0.69 |

0.61 |

|

95 |

0.49 |

0.5 |

0.15 |

0.52 |

0.43 |

0.13 |

0.45 |

0.52 |

0.45 |

|

120 |

0.39 |

0.4 |

0.145 |

0.42 |

0.34 |

0.13 |

0.37 |

0.42 |

0.36 |

|

150 |

0.31 |

0.32 |

0.145 |

0.35 |

0.28 |

0.125 |

0.3 |

0.35 |

0.3 |

|

185 |

0.25 |

0.26 |

0.145 |

0.29 |

0.22 |

0.125 |

0.26 |

0.29 |

0.25 |

|

240 |

0.195 |

0.2 |

0.14 |

0.24 |

0.175 |

0.125 |

0.21 |

0.24 |

0.21 |

|

300 |

0.155 |

0.16 |

0.14 |

0.21 |

0.14 |

0.12 |

0.185 |

0.21 |

0.19 |

|

400 |

0.12 |

0.13 |

0.14 |

0.19 |

0.115 |

0.12 |

0.165 |

0.19 |

0.18 |

Note : r = conductor resistance at operating temperature

x = reactance

z = impedance