RE-2Y(C)H 90°C / 300V

| STANDARDS | Basic design to EN 50288-7 |

| APPLICATION | Instrument cable minimizes noise and signal interference, delivering clean signals in harsh environments and general manufacturing operations. |

FIRE PERFORMANCE

|

Flame Retardance (Single Vertical Wire Test) |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

|

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

|

Halogen Free |

IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

|

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

|

Minimum Smoke Emission |

IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

|

No Toxic gases |

NES 02-713; NF C 20-454 |

|

Sunlight Resistance |

UL 1581 section 1200 |

|

Oil Resistance |

ICEA S-73-532** |

Note: Asterisk * denotes superseded standard, **Test temperature +60°C, duration 4h. Retention: min 60% of tensite strength/min.60% of elongation.

| VOLTAGE RATING | 300V |

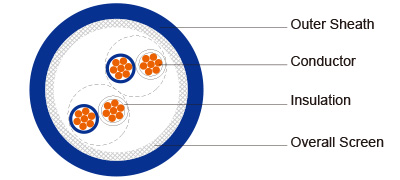

| CABLE CONSTRUCTION | |

| Conductor: | Annealed copper solid or plain copper stranded to IEC 60228 Class 2. |

| Insulation: | PE compound, EN 50290. 2-23. |

| Pair: | Two conductors twisted to form a pair |

| Lay-up: | Pairs laid up in layers of optimum pitch |

| Separator: | Polyester tape |

| Overall Screen: | Tinned copper wire braid |

| Outer sheath: | Thermoplastic LSZH compound type to EN 50290-2-27. |

| COLOUR CODE | |

| Insulation: | Black / White, continuously numbered on white core(1, 2..)for multipair. |

| Outer Sheath: | Black or blue for intrinsically safe systems |

| Physical AND THERMAL PROPERTIES | |

| Temperature Range During Operation (Fixed State): | -30°C – +70°C |

| Temperature Range During Installation (Mobile State): | -5°C – +50°C |

| Minimum Bending Radius: | 7.5 X Overall Diameter |

CONSTRUCTION PARAMETERS

|

Cable Code |

RE-2Y(C)H |

||

|

No. of Pairsx2xCross Section |

Copper Weight |

Approx. Weight |

|

|

No.x2xmm2 |

Kg/km |

Kg/km |

|

|

0.5mm2, Multipair |

|||

|

RE-2Y(C)H 1P0.5 |

1x2x0.50 |

8.3 |

110 |

|

RE-2Y(C)H 2P0.5 |

2x2x0.50 |

10.7 |

143 |

|

RE-2Y(C)H 3P0.5 |

3x2x0.50 |

11.1 |

158 |

|

RE-2Y(C)H 4P0.5 |

4x2x0.50 |

11.9 |

181 |

|

RE-2Y(C)H 6P0.5 |

6x2x0.50 |

13.6 |

230 |

|

RE-2Y(C)H 8P0.5 |

8x2x0.50 |

14.2 |

264 |

|

RE-2Y(C)H 12P0.5 |

12x2x0.50 |

16.4 |

343 |

|

RE-2Y(C)H 16P0.5 |

16x2x0.50 |

18.2 |

418 |

|

RE-2Y(C)H 20P0.5 |

20x2x0.50 |

19.7 |

487 |

|

RE-2Y(C)H 24P0.5 |

24x2x0.50 |

21.1 |

557 |

|

0.75mm2, Multipair |

|||

|

RE-2Y(C)H 1P0.75 |

1x2x0.75 |

8.7 |

119 |

|

RE-2Y(C)H 2P0.75 |

2x2x0.75 |

11.4 |

161 |

|

RE-2Y(C)H 3P0.75 |

3x2x0.75 |

11.9 |

185 |

|

RE-2Y(C)H 4P0.75 |

4x2x0.75 |

12.7 |

214 |

|

RE-2Y(C)H 6P0.75 |

6x2x0.75 |

14.6 |

278 |

|

RE-2Y(C)H 8P0.75 |

8x2x0.75 |

15.4 |

324 |

|

RE-2Y(C)H 12P0.75 |

12x2x0.75 |

17.8 |

427 |

|

RE-2Y(C)H 16P0.75 |

16x2x0.75 |

19.8 |

526 |

|

RE-2Y(C)H 20P0.75 |

20.x2x0.75 |

21.5 |

623 |

|

RE-2Y(C)H 24P0.75 |

24x2x0.75 |

23.1 |

714 |

|

1.0mm2, Multipair |

|||

|

RE-2Y(C)H 1P1.0 |

1x2x1.0 |

9.4 |

1.3.5 |

|

RE-2Y(C)H 2P1.0 |

2x2x1.0 |

12.3 |

184 |

|

RE-2Y(C)H 3P1.0 |

3x2x1.0 |

12.8 |

214 |

|

RE-2Y(C)H 4P1.0 |

4x2x1.0 |

13.7 |

251 |

|

RE-2Y(C)H 6P1.0 |

6x2x1.0 |

15.6 |

326 |

|

RE-2Y(C)H 8P1.0 |

8x2x1.0 |

16.4 |

382 |

|

RE-2Y(C)H 12P1.0 |

12x2x1.0 |

19.0 |

511 |

|

RE-2Y(C)H 16P1.0 |

16x2x1.0 |

21.2 |

636 |

|

RE-2Y(C)H 20P1.0 |

20.x2x1.0 |

23.5 |

775 |

|

RE-2Y(C)H 24P1.0 |

24x2x1.0 |

25.3 |

892 |

|

1.3mm2, Multipair |

|||

|

RE-2Y(C)H 1P1.3 |

1x2x1.3 |

9.7 |

140 |

|

RE-2Y(C)H 2P1.3 |

2x2x1.3 |

12.9 |

204 |

|

RE-2Y(C)H 3P1.3 |

3x2x1.3 |

13.5 |

242 |

|

RE-2Y(C)H 4P1.3 |

4x2x1.3 |

14.5 |

285 |

|

RE-2Y(C)H 6P1.3 |

6x2x1.3 |

16.7 |

375 |

|

RE-2Y(C)H 8P1.3 |

8x2x1.3 |

17.4 |

444 |

|

RE-2Y(C)H 12P1.3 |

12x2x1.3 |

20.2 |

599 |

|

RE-2Y(C)H 16P1.3 |

16x2x1.3 |

22.6 |

750 |

|

RE-2Y(C)H 20P1.3 |

20.x2x1.3 |

25.1 |

916 |

|

RE-2Y(C)H 24P1.3 |

24x2x1.3 |

27.0 |

1064 |

Note : Other conductor sizes & core configurations are available upon request

Electrical PROPERTIES

|

Conductor Area Size |

mm 2 |

0.5 |

0.75 |

1.0 |

1.3 |

1.5 |

|

|

Insulation thickness (nominal) |

mm |

0.4 |

0.4 |

0.4 |

0.45 |

0.45 |

|

|

Conductor resistance (20°C) |

Ω/km |

36.7 |

25 |

18.5 |

14.2 |

12.3 |

|

|

Insulation resistance (20°C) |

MΩ.km(Min.) |

5000 |

|||||

|

Mutual Capacitance (1 kHz) |

pF/m(Max.) |

||||||

|

≤ 4 pairs |

115 |

115 |

115 |

120 |

120 |

||

|

all other pairs |

90 |

90 |

90 |

105 |

105 |

||

|

Capacitance unbalance(1 kHz) |

pF/500 m (Max.) |

500 |

|||||

|

L / R (ratio) (max.) |

μH/Ω |

25 |

25 |

25 |

40 |

40 |

|

|

Operating voltage Urms |

V |

300 |

300 |

300 |

300 |

300 |

|

|

Test Voltage |

Core to Core |

V |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Core to Screen |

V |

1500 |

1500 |

1500 |

1500 |

1500 |

|