| Application | The cables are designed for use as subscriber distribution cables and as connection between central offices in local access networks. The cables are unfilled and capable of being pressurized when installed. The cables are suitable for installation in ducts. |

| Standards | CW 1171 (For unscreened cable) CW 1179 (For screened cable) CW 1252 (For self-supporting cable) |

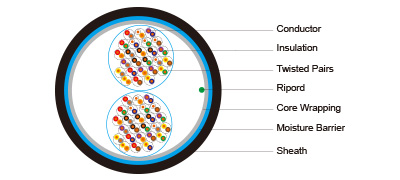

| Conductors: | Solid annealed bare copper, 0.32/0.4/0.5/0.63/0.9mm as per BS 6360/IEC 60228 Class 1 |

| Insulation: | Solid polyethylene as per BS EN 50290-2-23/BS 6234/IEC 60708 |

| Twisted Pairs: | Insulated conductors are twisted into pairs with varying lay length to minimize crosstalk. |

| Cabling Element: | Twisted Pairs |

| Cable Core Assembly: | Cables with 100 pairs or less are composed of 25-pair units or 12/13-pair units; cables with over 100 pairs are composed of 25, 50 or 100-pair units. Standard construction is per CW 1171 given in Cable Make Up Chart |

| Core Wrapping: | One or more non-hygroscopic polyester tapes are helically or longitudinally laid with an overlap. These tapes furnish thermal, mechanical as well as high dielectric protection between shielding and individual conductors |

| Moisture Barrier (optional): | A layer of aluminium tape (0.15mm) coated with PE-copolymer on one or both sides is applied longitudinally with overlap over the cable core to provide shielding coverage and ensure a barrier against water vapor |

| Sheath: | Black low density polyethylene as per BS 6234/IEC 60708, being able to withstand exposure to sunlight, temperature variations, ground chemicals and other environmental contaminants |

| Ripcord: | Ripcord may be provided for slitting the sheath longitudinally to facilitate its removal |

| Spare Pairs (optional): | Spare pairs may be incorporated for 200 and larger pair cables |

| Continuity Wire (optional): | Tinned copper drain wire may be longitudinally laid to ensure electrical continuity of the screen |

Electrical & Mechanical Properties

|

Nominal Conductor Diameter |

mm |

0.32 |

0.4 |

0.5 |

0.63 |

0.9 |

|

Conductor Gauge Size |

AWG |

28 |

26 |

24 |

22 |

19 |

|

Conductor Size |

mm2 |

0.08 |

0.126 |

0.196 |

0.312 |

0.636 |

|

Maximum Average Conductor Resistance @20°C |

Ω/km |

223 |

143 |

91 |

58 |

28 |

|

Minimum Insulation Resistance @500V DC |

MΩ.km |

6500 |

6500 |

6500 |

6500 |

6500 |

|

Maximum Average Mutual Capacitance @800Hz |

nF/km |

53/68* |

53 |

53 |

56 |

59 |

|

Maximum Individual Mutual Capacitance @800Hz (for 99% cases) |

nF/km |

60/75* |

60 |

60 |

60 |

64 |

|

Maximum Individual Capacitance Unbalance @800Hz pair-to-pair |

pF/500m |

275 |

275 |

275 |

275 |

275 |

|

Maximum Conductor Loop Resistance @20°C |

Ω/km |

470 |

300 |

192 |

114 |

60 |

|

Impedance @1KHz |

Ω |

1000 |

994 |

796 |

660 |

445 |

|

Impedance @100KHz |

Ω |

156 |

147 |

134 |

125 |

122 |

|

Impedance @512KHz |

Ω |

122 |

120 |

118 |

117 |

116 |

|

Impedance @1MHz |

Ω |

120 |

117 |

115 |

114 |

113 |

|

Maximum Average Attenuation @0.8KHz |

dB/km |

1.76 |

1.64 |

1.3 |

1.04 |

0.74 |

|

Maximum Average Attenuation @1KHz |

dB/km |

1.8 |

1.68 |

1.35 |

1.08 |

0.76 |

|

Maximum Average Attenuation @3KHz |

dB/km |

3.4 |

3.18 |

2.52 |

2.01 |

1.42 |

|

Maximum Average Attenuation @150KHz |

dB/km |

16.8 |

11.4 |

8.3 |

6.2 |

4.4 |

|

Maximum Average Attenuation @772KHz |

dB/km |

29.5 |

24.3 |

19.4 |

15.4 |

10.8 |

|

Maximum Average Attenuation @1000KHz |

dB/km |

33.5 |

27.1 |

21.4 |

17.5 |

12.8 |

|

Dielectric Strength Conductor to Conductor (3secs) |

V DC |

500 |

500 |

500 |

500 |

500 |

|

Nominal Insulation Thickness |

mm |

0.145/0.08** |

0.175 |

0.2 |

0.26 |

0.3 |

|

Nominal Insulated Conductor Diameter |

mm |

0.61/0.48** |

0.75 |

0.9 |

1.15 |

1.5 |

* Mutual capacitance values may be increased by 3% for cables with a nominal number of pairs less than 400.

** The values apply to 4000 and 4800 pairs 0.32mm cable only.

Mechanical and Thermal Properties

Temperature range during operation (fixed state): -30°C – +70°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 10 x Overall Diameter (unarmoured cables);15 x Overall Diameter (armoured cables)

Colour Code Standard colour code is per CW 1171 given in Colour Code Chart

Dimensions And Weight Solid PE Insulated & PE Sheathed Air Core Cables to CW 1171* Mutual capacitance values may be increased by 3% for cables with a nominal number of pairs less than 400.

** The values apply to 4000 and 4800 pairs 0.32mm cable only.

Mechanical and Thermal Properties

Temperature range during operation (fixed state): -30°C – +70°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 10 x Overall Diameter (unarmoured cables);15 x Overall Diameter (armoured cables)

Colour Code Standard colour code is per CW 1171 given in Colour Code Chart

Dimensions And Weight Solid PE Insulated & PE Sheathed Air Core Cables to CW 1171

|

Cable Code |

Number of Pairs |

Minimum Sheath Thickness |

Maximum Overall |

Nominal Weight |

|

mm |

Diameter |

kg/km |

||

|

|

mm |

|

||

|

0.32mm Conductor, 0.61mm Insulated Wire |

||||

|

UE-TP1171-2Y(L)2Y-50P032 |

50 |

1.6 |

14 |

140 |

|

UE-TP1171-2Y(L)2Y-100P032 |

100 |

1.6 |

17 |

280 |

|

UE-TP1171-2Y(L)2Y-200P032 |

200 |

1.7 |

22 |

480 |

|

UE-TP1171-2Y(L)2Y-300P032 |

300 |

1.8 |

26 |

680 |

|

UE-TP1171-2Y(L)2Y-400P032 |

400 |

1.8 |

29.5 |

880 |

|

UE-TP1171-2Y(L)2Y-500P032 |

500 |

1.9 |

32 |

1080 |

|

UE-TP1171-2Y(L)2Y-600P032 |

600 |

1.9 |

34 |

1281 |

|

UE-TP1171-2Y(L)2Y-800P032 |

800 |

2 |

39 |

1681 |

|

UE-TP1171-2Y(L)2Y-1000P032 |

1000 |

2.1 |

42.5 |

2081 |

|

UE-TP1171-2Y(L)2Y-1200P032 |

1200 |

2.2 |

47 |

2482 |

|

UE-TP1171-2Y(L)2Y-1600P032 |

1600 |

2.3 |

53 |

2883 |

|

UE-TP1171-2Y(L)2Y-2000P032 |

2000 |

2.4 |

58.5 |

3284 |

|

UE-TP1171-2Y(L)2Y-2400P032 |

2400 |

2.5 |

62 |

3681 |

|

UE-TP1171-2Y(L)2Y-3200P032 |

3200 |

2.6 |

70 |

4082 |

|

UE-TP1171-2Y(L)2Y-4000P032 |

4000 |

2.6 |

66.0* |

4883 |

|

UE-TP1171-2Y(L)2Y-4800P032 |

4800 |

2.7 |

71.0* |

5681 |

|

0.4mm Conductor, 0.75mm Insulated Wire |

||||

|

UE-TP1171-2Y(L)2Y-50P04 |

50 |

1.6 |

16 |

211 |

|

UE-TP1171-2Y(L)2Y-100P04 |

100 |

1.7 |

20.5 |

380 |

|

UE-TP1171-2Y(L)2Y-200P04 |

200 |

1.8 |

26 |

708 |

|

UE-TP1171-2Y(L)2Y-300P04 |

300 |

1.9 |

30.5 |

1034 |

|

UE-TP1171-2Y(L)2Y-400P04 |

400 |

1.9 |

35 |

1358 |

|

UE-TP1171-2Y(L)2Y-500P04 |

500 |

2 |

37.5 |

1703 |

|

UE-TP1171-2Y(L)2Y-600P04 |

600 |

2.1 |

40.5 |

2016 |

|

UE-TP1171-2Y(L)2Y-800P04 |

800 |

2.2 |

46.5 |

2639 |

|

UE-TP1171-2Y(L)2Y-1000P04 |

1000 |

2.3 |

51.5 |

3264 |

|

UE-TP1171-2Y(L)2Y-1200P04 |

1200 |

2.4 |

56 |

3873 |

|

UE-TP1171-2Y(L)2Y-1600P04 |

1600 |

2.6 |

65.5 |

4819 |

|

UE-TP1171-2Y(L)2Y-2000P04 |

2000 |

2.6 |

70 |

6731 |

|

0.5mm Conductor, 0.9mm Insulated Wire |

||||

|

UE-TP1171-2Y(L)2Y-50P05 |

50 |

1.6 |

19 |

305 |

|

UE-TP1171-2Y(L)2Y-100P05 |

100 |

1.7 |

23.5 |

561 |

|

UE-TP1171-2Y(L)2Y-200P05 |

200 |

1.9 |

30.5 |

1074 |

|

UE-TP1171-2Y(L)2Y-300P05 |

300 |

2 |

37 |

1582 |

|

UE-TP1171-2Y(L)2Y-400P05 |

400 |

2.1 |

42.5 |

2093 |

|

UE-TP1171-2Y(L)2Y-500P05 |

50 |

2.2 |

46 |

2577 |

|

UE-TP1171-2Y(L)2Y-600P05 |

600 |

2.2 |

49.5 |

3073 |

|

UE-TP1171-2Y(L)2Y-800P05 |

800 |

2.4 |

56.5 |

4033 |

|

UE-TP1171-2Y(L)2Y-1000P05 |

1000 |

2.5 |

62.5 |

5015 |

|

UE-TP1171-2Y(L)2Y-1200P05 |

1200 |

2.6 |

69 |

5959 |

|

0.63mm Conductor, 1.15mm Insulated Wire |

||||

|

UE-TP1171-2Y(L)2Y-50P063 |

50 |

1.7 |

22 |

416 |

|

UE-TP1171-2Y(L)2Y-100P063 |

100 |

1.8 |

28 |

782 |

|

UE-TP1171-2Y(L)2Y-200P063 |

200 |

2 |

37.5 |

1505 |

|

UE-TP1171-2Y(L)2Y-300P063 |

300 |

2.2 |

46 |

2238 |

|

UE-TP1171-2Y(L)2Y-400P063 |

400 |

2.3 |

52.5 |

2944 |

|

UE-TP1171-2Y(L)2Y-500P063 |

500 |

2.4 |

56.5 |

3633 |

|

UE-TP1171-2Y(L)2Y-800P063 |

800 |

2.7 |

70.5 |

5722 |

|

0.9mm Conductor, 1.5mm Insulated Wire |

||||

|

UE-TP1171-2Y(L)2Y-50P09 |

50 |

1.8 |

27.5 |

1000 |

|

UE-TP1171-2Y(L)2Y-100P09 |

100 |

2 |

38 |

1670 |

*These cables have a reduced nominal insulation thickness of 0.08mm