| Application and Description | XHHW XLPO type TC Control Cable is for use in industrial power or control circuits where small diameter, flame retardant cables are desired. Primary installations include cable trays, raceways, and outdoor locations where supported by a messenger wire. Type TC Control Cable is also listed for direct burial and for use in Class 1, Division 2 hazardous locations and Class 1 control circuits. Constructions witd 3 or more conductors are listed for exposed runs (TC-ER) per NEC 336.10. Conductors may be used in wet or dry locations at temperatures not to exceed 90°C. |

| Cable Construction | |

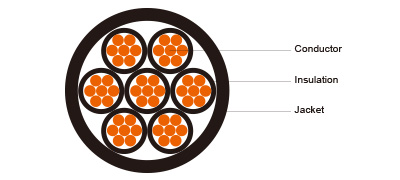

| Conductor | Stranded bare annealed copper |

| Insulation | Flame-retardant and moisture resistant Cross-Linked Polyetdylene (XLPE) |

| Jacket | Low smoke halogen free polyethylene jacket |

| Color | upon request, black is preferable |

| Technical Characteristics | - UL 1277 - Electrical Power and Control Tray Cables. - UL 1581 - Electrical Wires, Cables and Flexible Cords - ICEA S-58-679 Metdod 1 - UL 1685 - UL Flame Exposure Test (70,000 Btu/hr). - ICEA T-29-520 - Vertical Cable Tray Flame Test (210,000 Btu/hr). - IEEE 1202 - Flame Testing of Cables for Use in Cable Tray in Industrial and Commercial Occupancies (70,000 Btu/hr) - ICEA S-95-658 (NEMA WC 70) RoHS |

Cable Parameter

|

NO.OF CORES |

NOMINAL JACKET THICKNESS INCH/MM |

NOMINAL OVERALL DIAMETER INCH/MM |

CABLE WEIGHT LBS/KFT KG/KM |

|||

|

AWG 14 (7 strands) |

||||||

|

2 |

0.045 |

1.14 |

0.349 |

8.86 |

63 |

94 |

|

3 |

0.045 |

1.14 |

0.370 |

9.40 |

87 |

129 |

|

4 |

0.045 |

1.14 |

0.403 |

10.24 |

106 |

157 |

|

5 |

0.045 |

1.14 |

0.440 |

11.18 |

125 |

186 |

|

6 |

0.045 |

1.14 |

0.479 |

12.17 |

146 |

218 |

|

7 |

0.045 |

1.14 |

0.479 |

12.17 |

164 |

245 |

|

8 |

0.060 |

1.52 |

0.549 |

13.94 |

201 |

299 |

|

9 |

0.060 |

1.52 |

0.588 |

14.94 |

223 |

332 |

|

10 |

0.060 |

1.52 |

0.638 |

16.21 |

247 |

367 |

|

12 |

0.060 |

1.52 |

0.659 |

16.74 |

285 |

424 |

|

15 |

0.060 |

1.52 |

0.730 |

18.54 |

347 |

517 |

|

19 |

0.060 |

1.52 |

0.768 |

19.51 |

424 |

630 |

|

20 |

0.060 |

1.52 |

0.808 |

20.52 |

446 |

664 |

|

25 |

0.080 |

2.03 |

0.938 |

23.83 |

582 |

866 |

|

30 |

0.080 |

2.03 |

0.991 |

25.17 |

680 |

1012 |

|

37 |

0.080 |

2.03 |

1.067 |

27.10 |

818 |

1217 |

|

AWG 12 (7 strands) |

||||||

|

2 |

0.045 |

1.14 |

0.384 |

9.75 |

85 |

127 |

|

3 |

0.045 |

1.14 |

0.408 |

10.36 |

115 |

172 |

|

4 |

0.045 |

1.14 |

0.445 |

11.30 |

147 |

219 |

|

5 |

0.045 |

1.14 |

0.487 |

12.37 |

171 |

255 |

|

6 |

0.060 |

1.52 |

0.562 |

14.27 |

217 |

323 |

|

7 |

0.060 |

1.52 |

0.562 |

14.27 |

244 |

363 |

|

8 |

0.060 |

1.52 |

0.607 |

15.42 |

275 |

410 |

|

9 |

0.060 |

1.52 |

0.651 |

16.54 |

307 |

457 |

|

10 |

0.060 |

1.52 |

0.709 |

18.01 |

340 |

506 |

|

12 |

0.060 |

1.52 |

0.732 |

18.59 |

396 |

589 |

|

15 |

0.060 |

1.52 |

0.813 |

20.65 |

484 |

721 |

|

19 |

0.080 |

2.03 |

0.896 |

22.76 |

628 |

934 |

|

20 |

0.080 |

2.03 |

0.942 |

23.93 |

661 |

984 |

|

25 |

0.080 |

2.03 |

1.043 |

26.49 |

811 |

1207 |

|

30 |

0.080 |

2.03 |

1.104 |

28.04 |

953 |

1418 |

|

37 |

0.080 |

2.03 |

1.190 |

30.23 |

1152 |

1714 |

|

AWG 10 (7 strands) |

||||||

|

2 |

0.045 |

1.14 |

0.431 |

10.95 |

116 |

172 |

|

3 |

0.045 |

1.14 |

0.459 |

11.66 |

161 |

239 |

|

4 |

0.045 |

1.14 |

0.502 |

12.75 |

205 |

306 |

|

5 |

0.060 |

1.52 |

0.581 |

14.76 |

260 |

387 |

|

6 |

0.060 |

1.52 |

0.632 |

16.05 |

306 |

455 |

|

7 |

0.060 |

1.52 |

0.632 |

16.05 |

346 |

514 |

|

8 |

0.060 |

1.52 |

0.685 |

17.40 |

392 |

583 |

|

9 |

0.060 |

1.52 |

0.736 |

18.69 |

437 |

651 |

|

10 |

0.060 |

1.52 |

0.803 |

20.40 |

485 |

721 |

|

12 |

0.080 |

2.03 |

0.870 |

22.10 |

599 |

892 |

|

15 |

0.080 |

2.03 |

0.964 |

24.49 |

733 |

1091 |

|

19 |

0.080 |

2.03 |

1.014 |

25.76 |

901 |

1340 |

|

20 |

0.080 |

2.03 |

1.066 |

27.08 |

949 |

1412 |

|

25 |

0.080 |

2.03 |

1.184 |

30.07 |

1168 |

1739 |

|

30 |

0.080 |

2.03 |

1.254 |

31.85 |

1379 |

2052 |

|

37 |

0.080 |

2.03 |

1.355 |

34.42 |

1674 |

2491 |