| Application and Description | NYCWY Power cables is for energy supply, preferably used for underground laying, especially in subscriber networks, power station as well as control impulses and test data. Overall, where increased electrical and also mechanical protection are required. These cables are installed in open air, in underground, in water, indoors and in cable ducts. The corrugated concentric conductor (CW) is allowed to use as neutral, protective or eartd conductor. Simultaneously, tdis also is permitted to apply as a screen for example eartded-connected protection against contact. Due to tde typical construction of corrugated concentric conductors (Ceander), are possible to obtain many more cable joints, witdout cutting any conductor. In tdat way tde operating reliability is guaranteed. |

| Standard and Approval | VDE0276 part 603, CENELEC HD603 S1, IEC 60502 |

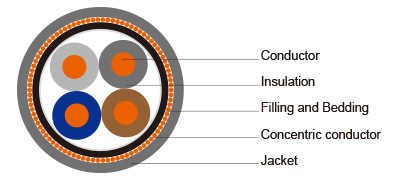

| Cable Construction | - Plain copper conductors solid or stranded versions, conductor types 10-16 mm² round, solid conductors (re) alt. 10-25 mm², stranded conductor (rm), 35-240 mm², sector shaped conductor, stranded (sm) - to DIN VDE 0295 cl. 1 or cl. 2, BS 6360 cl. 1, IEC 60228 and HD 383 - PVC insulation DIV4 to HD 603.1 - Color coded to DIN VDE 0293-308, 0276 part 603 or HD 186 - PVC bedding - Concentric conductor: ceander shaped copper wires and helical copper tape - PVC outer jacket DMV5 to HD 603.1 |

| Technical Characteristics | - Working voltage: 600/1000 volts - Test voltage: 4000 volts - Flexing bending radius: 15 x Ø - Static bending radius: 12 x Ø - Flexing temperature: -5º C to +50º C - Fixed installation temperature: - 40º C to +70º C - Short circuit temperature: +160º C - Flame retardant: IEC 60332.1 - Insulation resistance: 100 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

STRANDED CONDUCTOR TYPE |

NOMINAL OVERALL DIAMETER MM |

NOMINAL COPPER WEIGHT KG/KM |

NOMINAL CABLE WEIGHT KG/KM |

|

8 |

2 x 10.0 |

re / 10.0 |

19 |

312 |

650 |

|

6 |

2 x 16.0 |

re / 16.0 |

21.5 |

489 |

850 |

|

4 |

2 x 25.0 |

rm / 25.0 |

24.5 |

763 |

1210 |

|

8 |

3 x 10.0 |

re / 10.0 |

19.5 |

408 |

730 |

|

6 |

3 x 16.0 |

re / 16.0 |

22 |

643 |

1000 |

|

4 |

3 x 25.0 |

rm / 16.0 |

26 |

902 |

1550 |

|

4 |

3 x 25.0 |

rm / 25.0 |

26 |

1003 |

1600 |

|

2 |

3 x 35.0 |

sm / 35.0 |

27.5 |

1402 |

1850 |

|

2 |

3 x 35.0 |

sm / 16.0 |

27 |

1190 |

1750 |

|

1 |

3 x 50.0 |

sm / 50.0 |

29.5 |

2000 |

2450 |

|

1 |

3 x 50.0 |

sm / 25.0 |

29 |

1723 |

2250 |

|

2/0 |

3 x 70.0 |

sm / 70.0 |

34 |

2796 |

3350 |

|

2/0 |

3 x 70.0 |

sm / 35.0 |

33 |

2410 |

2950 |

|

3/0 |

3 x 95.0 |

sm / 95.0 |

38.5 |

3791 |

4550 |

|

3/0 |

3 x 95.0 |

sm / 50.0 |

38 |

3296 |

4100 |

|

4/0 |

3 x 120.0 |

sm / 70.0 |

41 |

4236 |

5050 |

|

4/0 |

3 x 120.0 |

sm / 120.0 |

42 |

4786 |

5550 |

|

300mcm |

3 x 150.0 |

sm / 70.0 |

45 |

5100 |

6000 |

|

300mcm |

3 x 150.0 |

sm / 150.0 |

46 |

5970 |

6900 |

|

350mcm |

3 x 185.0 |

sm / 95.0 |

50 |

6383 |

7550 |

|

350mcm |

3 x 185.0 |

sm / 185.0 |

51 |

7363 |

8500 |

|

500mcm |

3 x 240.0 |

sm / 120.0 |

57 |

8242 |

9950 |

|

8 |

4 x 10.0 |

re / 10.0 |

20.5 |

504 |

890 |

|

6 |

4 x 16.0 |

re / 16.0 |

23.5 |

796 |

1250 |

|

4 |

4 x 25.0 |

rm / 16.0 |

28 |

1142 |

1800 |

|

2 |

4 x 35.0 |

sm / 16.0 |

29 |

1526 |

2050 |

|

1 |

4 x 50.0 |

sm / 25.0 |

33 |

2203 |

2700 |

|

2/0 |

4 x 70.0 |

sm / 35.0 |

37 |

3082 |

3750 |

|

3/0 |

4 x 95.0 |

sm / 50.0 |

43.5 |

4208 |

5000 |

|

4/0 |

4 x 120.0 |

sm / 70.0 |

47 |

5388 |

6350 |

|

300mcm |

4 x 150.0 |

sm / 70.0 |

51 |

6540 |

7650 |

|

350mcm |

4 x 185.0 |

sm / 95.0 |

56 |

8159 |

9350 |

|

500mcm |

4 x 240.0 |

sm / 120.0 |

62.5 |

10546 |

11600 |