| Application and Description | N2XH power cables with enhanced resistance to fire are used mostly in areas where harm to human life or material must be prevented in case of fire such as industrial and public buildings, hotels, subway systems, hospitals etc. These cables are suitable for dry and wet environments as well as for outer application but are not suitable for direct burial into eartd or water. |

| Standard and Approval | VDE 0276 part 604, VDE 0482-266-2, DIN EN 60332-3 / EN50266-2 |

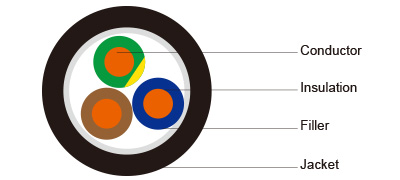

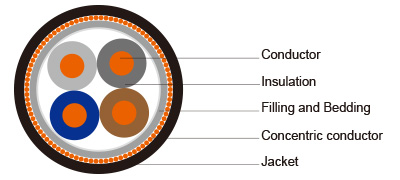

| Cable Construction | 1- Solid or stranded plain copper conductor - to DIN VDE 0295 cl. 1, cl. 2, BS 6360 cl. 1, cl. 2 and IEC 60228 cl 1, cl. 2 2- XLPE insulation type 2XI1, to HD 604 S1 - Color coded to DIN VDE 0293-308 - Green-yellow ground conductor (3 conductors and above) - Special LSOH filler - For N2XCH version witd concentric conductor: 4-plain round copper wires and one or two transverse counter helix of copper tapes 5-Thermoplastic polyolefin compound outer jacket type HM4, to HD 604 S1 |

| Technical Characteristics | - Working voltage: 600/1000 volts - Test voltage: 4000 volts - Minimum bending radius: 12 x Ø - Flexing temperature: +5º C to +50º C - Fixed installation temperature: - 40º C to +90º C - Short circuit temperature: +250º C - Flame retardant: VDE 0482 part 266-2, DIN EN 50266-2 / IEC 60332-3 - Low corrosiveness of combustion gases to DIN VDE 0482 part 267/ EN 50267-2-2/IEC 60754-2 - Halogen-free to DIN VDE 0482 part 267 /EN 50267-2-1/IEC 60754-1 - Smoke density to DIN VDE 0482 part 268/HD 606/BS 7622 PT1,PT2/EN 50268-1,-2/IEC 61034-1,-2 - Insulation resistance: 20 MΩ x km |

N2XCH

Cable Parameter

N2XH

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

CONDUCTOR TYPE |

INSULATION THICKNESS MM |

NOMINAL OVERALL DIAMETER MM |

COPPER WEIGHT KG / KM |

CABLE WEIGHT KG / KM |

|

12 |

1x4 |

re |

0.7 |

7.5 |

38 |

140 |

|

10 |

1x6 |

re |

0.7 |

8.0 |

58 |

160 |

|

8 |

1x10 |

re |

0.7 |

8.8 |

96 |

210 |

|

6 |

1x16 |

rm |

0.7 |

9.7 |

154 |

270 |

|

4 |

1x25 |

rm |

0.9 |

10.6 |

240 |

380 |

|

2 |

1x35 |

rm |

0.9 |

12.7 |

336 |

490 |

|

1 |

1x50 |

rm |

1.0 |

14.1 |

480 |

620 |

|

2/0 |

1x70 |

rm |

1.1 |

16.0 |

672 |

830 |

|

3/0 |

1x95 |

rm |

1.1 |

17.9 |

912 |

1200 |

|

4/0 |

1x120 |

rm |

1.2 |

19.5 |

1152 |

1500 |

|

300mcm |

1x150 |

rm |

1.4 |

21.6 |

1440 |

1700 |

|

350mcm |

1x185 |

rm |

1.6 |

23.8 |

1776 |

2200 |

|

500mcm |

1x240 |

rm |

1.7 |

25.3 |

2304 |

2750 |

|

750mcm |

1x300 |

rm |

1.8 |

29.0 |

2880 |

3300 |

|

- |

1x400 |

rm |

2.0 |

37.0 |

3840 |

4420 |

|

- |

1x500 |

rm |

2.2 |

40.0 |

4800 |

5460 |

|

16 |

2x1.5 |

re |

0.7 |

11.1 |

29 |

180 |

|

14 |

2x2.5 |

re |

0.7 |

11.9 |

48 |

210 |

|

12 |

2x4 |

re |

0.7 |

12.7 |

77 |

270 |

|

10 |

2x6 |

re |

0.7 |

13.7 |

115 |

340 |

|

8 |

2x10 |

re |

0.7 |

15.3 |

192 |

450 |

|

6 |

2x16 |

rm |

0.7 |

17.3 |

307 |

600 |

|

4 |

2x25 |

rm |

0.9 |

21.1 |

480 |

980 |

|

16 |

3x1.5 |

re |

0.7 |

11.5 |

43 |

179 |

|

14 |

3x2.5 |

re |

0.7 |

12.4 |

72 |

225 |

|

12 |

3x4 |

re |

0.7 |

13.3 |

115 |

291 |

|

10 |

3x6 |

re |

0.7 |

14.4 |

173 |

371 |

|

8 |

3x10 |

re |

0.7 |

16.1 |

288 |

523 |

|

6 |

3x16 |

rm |

0.7 |

18.2 |

461 |

773 |

|

4 |

3x25 |

rm |

0.9 |

22.3 |

720 |

1200 |

|

2 |

3x35 |

rm |

0.9 |

24.9 |

1008 |

1600 |

|

1 |

3x50 |

rm |

1.0 |

26.0 |

1440 |

1800 |

|

16 |

4x1.5 |

re |

0.7 |

12.2 |

58 |

208 |

|

14 |

4x2.5 |

re |

0.7 |

13.2 |

96 |

265 |

|

12 |

4x4 |

re |

0.7 |

14.2 |

154 |

352 |

|

10 |

4x6 |

re |

0.7 |

15.4 |

230 |

454 |

|

8 |

4x10 |

re |

0.7 |

17.5 |

384 |

647 |

|

6 |

4x16 |

rm |

0.7 |

19.7 |

614 |

964 |

|

4 |

4x25 |

rm |

0.9 |

24.5 |

960 |

1446 |

|

2 |

4x35 |

rm |

0.9 |

27.1 |

1344 |

1906 |

|

1 |

4x50 |

sm |

1.0 |

29.6 |

1920 |

2530 |

|

2/0 |

4x70 |

sm |

1.1 |

32.9 |

2688 |

3418 |

|

3/0 |

4x95 |

sm |

1.1 |

37.5 |

3648 |

4574 |

|

4/0 |

4x120 |

sm |

1.2 |

41.5 |

4608 |

5300 |

|

300mcm |

4x150 |

sm |

1.4 |

46.3 |

5760 |

6350 |

|

350mcm |

4x185 |

sm |

1.6 |

49.0 |

7104 |

7800 |

|

500mcm |

4x240 |

sm |

1.7 |

54.0 |

9216 |

10300 |

|

16 |

5x1.5 |

re |

0.7 |

13.1 |

72 |

243 |

|

14 |

5x2.5 |

re |

0.7 |

14.2 |

120 |

310 |

|

12 |

5x4 |

re |

0.7 |

15.3 |

192 |

413 |

|

10 |

5x6 |

re |

0.7 |

16.6 |

288 |

536 |

|

8 |

5x10 |

re |

0.7 |

19.0 |

480 |

776 |

|

6 |

5x16 |

rm |

0.7 |

21.4 |

768 |

1165 |

|

4 |

5x25 |

rm |

0.9 |

28.0 |

1200 |

1766 |

|

16 |

7x1.5 |

re |

0.7 |

12.7 |

101 |

206 |

|

14 |

7x2.5 |

re |

0.7 |

13.5 |

168 |

287 |

|

12 |

7x4 |

re |

0.7 |

17.0 |

269 |

530 |

|

16 |

10x1.5 |

re |

0.7 |

13.8 |

144 |

287 |

|

14 |

10x2.5 |

re |

0.7 |

15.9 |

240 |

472 |

|

16 |

12x1.5 |

re |

0.7 |

15.2 |

173 |

328 |

|

14 |

12x2.5 |

re |

0.7 |

17.3 |

288 |

472 |

|

12 |

12x4 |

re |

0.7 |

21.0 |

461 |

820 |

|

16 |

14x1.5 |

re |

0.7 |

15.7 |

202 |

383 |

|

14 |

14x2.5 |

re |

0.7 |

17.6 |

336 |

670 |

|

16 |

19x1.5 |

re |

0.7 |

17.3 |

274 |

484 |

|

14 |

19x2.5 |

re |

0.7 |

21.3 |

456 |

840 |

|

16 |

24x1.5 |

re |

0.7 |

20.2 |

346 |

603 |

|

14 |

24x2.5 |

re |

0.7 |

24.6 |

576 |

1050 |

|

16 |

30x1.5 |

re |

0.7 |

22.6 |

432 |

730 |

|

14 |

30x2.5 |

re |

0.7 |

24.5 |

720 |

1230 |

|

16 |

40x1.5 |

re |

0.7 |

26.2 |

576 |

1200 |

N2XCH

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

CONDUCTOR TYPE |

CONCENTRIC CONDUCTOR CROSS SECTION MM² |

NOMINAL OVERALL DIAMETER MM |

COPPER WEIGHT KG / KM |

CABLE WEIGHT KG / KM |

|

16 |

1x1.5 |

re |

1.5 |

7.9 |

27 |

98 |

|

14 |

1x2.5 |

re |

2.5 |

8.5 |

47 |

122 |

|

12 |

1x4.0 |

re |

4 |

9.4 |

74 |

163 |

|

10 |

1x6.0 |

re |

6 |

9.9 |

108 |

203 |

|

8 |

1x10 |

re |

10 |

11.3 |

182 |

286 |

|

6 |

1x16 |

re |

16 |

12.8 |

297 |

410 |

|

4 |

1x25 |

rm |

25 |

12.9 |

465 |

606 |

|

2 |

1x35 |

rm |

35 |

16.4 |

654 |

807 |

|

16 |

2x1.5 |

re |

1.5 |

13 |

45 |

230 |

|

14 |

2x2.5 |

re |

2.5 |

13.7 |

68 |

273 |

|

12 |

2x4.0 |

re |

4 |

15.9 |

110 |

375 |

|

10 |

2x6.0 |

re |

6 |

17.1 |

164 |

458 |

|

8 |

2x10 |

re |

10 |

19.1 |

274 |

619 |

|

6 |

2x16 |

re |

16 |

21 |

435 |

841 |

|

4 |

2x25 |

rm |

25 |

25.1 |

703 |

1276 |

|

2 |

2x35 |

rm |

35 |

27.8 |

980 |

1642 |

|

1 |

2x50 |

rm |

50 |

31.5 |

1343 |

2193 |

|

16 |

3x1.5 |

re |

1.5 |

13.5 |

56 |

252 |

|

14 |

3x2.5 |

re |

2.5 |

14.3 |

90 |

305 |

|

12 |

3x4.0 |

re |

4 |

16.6 |

147 |

425 |

|

10 |

3x6.0 |

re |

6 |

17.7 |

243 |

528 |

|

8 |

3x10 |

re |

10 |

20 |

365 |

724 |

|

6 |

3x16 |

re |

16 |

22.1 |

580 |

999 |

|

4 |

3x25 |

rm |

16 |

27.8 |

855 |

1440 |

|

4 |

3x25 |

rm |

25 |

26.6 |

938 |

1524 |

|

2 |

3x35 |

rm |

16 |

29.1 |

1127 |

1813 |

|

2 |

3x35 |

rm |

35 |

29.4 |

1317 |

1987 |

|

1 |

3x50 |

rm |

25 |

32.7 |

1581 |

2415 |

|

2 |

3x35 |

sm |

35 |

27.1 |

1339 |

1644 |

|

2 |

3x35 |

sm |

16 |

26.6 |

1161 |

1627 |

|

1 |

3x50 |

sm |

25 |

29.6 |

1593 |

2174 |

|

1 |

3x50 |

sm |

50 |

30.6 |

1819 |

2260 |

|

2/0 |

3x70 |

sm |

35 |

33.6 |

2265 |

2932 |

|

2/0 |

3x70 |

sm |

70 |

34.1 |

2584 |

3097 |

|

3/0 |

3x95 |

sm |

50 |

38.2 |

3151 |

4004 |

|

3/0 |

3x95 |

sm |

95 |

39.4 |

3692 |

4336 |

|

4/0 |

3x120 |

sm |

70 |

38.3 |

4038 |

4925 |

|

4/0 |

3x120 |

sm |

120 |

41.6 |

4443 |

5124 |

|

300 |

3x150 |

sm |

70 |

44.7 |

4827 |

5890 |

|

300 |

3x150 |

sm |

150 |

45.8 |

5543 |

6352 |

|

350 |

3x185 |

sm |

95 |

49 |

6051 |

7329 |

|

400 |

3x240 |

sm |

120 |

54.5 |

7881 |

9399 |

|

16 |

4x1.5 |

re |

1.5 |

14.3 |

70 |

284 |

|

14 |

4x2.5 |

re |

2.5 |

16.3 |

136 |

382 |

|

12 |

4x4.0 |

re |

4 |

17.8 |

183 |

494 |

|

10 |

4x6.0 |

re |

6 |

19 |

297 |

620 |

|

8 |

4x10 |

re |

10 |

21.5 |

457 |

860 |

|

6 |

4x16 |

re |

16 |

23.8 |

725 |

1196 |

|

4 |

4x25 |

rm |

16 |

29 |

1090 |

1764 |

|

2 |

4x35 |

rm |

16 |

32 |

1456 |

2246 |

|

1 |

4x50 |

rm |

25 |

36.4 |

1998 |

3024 |

|

2 |

4x35 |

sm |

16 |

29.8 |

1495 |

2060 |

|

1 |

4x50 |

sm |

25 |

33.1 |

2044 |

2730 |

|

2/0 |

4x70 |

sm |

35 |

38.4 |

2911 |

3758 |

|

3/0 |

4x95 |

sm |

50 |

42.6 |

4041 |

5054 |

|

4/0 |

4x120 |

sm |

70 |

43.1 |

5162 |

6246 |

|

300 |

4x150 |

sm |

70 |

50.7 |

6214 |

7548 |

|

350 |

4x185 |

sm |

95 |

55.3 |

7826 |

9374 |

|

400 |

4x240 |

sm |

120 |

62.3 |

10150 |

12124 |

|

16 |

7X1.5 |

re |

2.5 |

14.5 |

132.0 |

320.0 |

|

14 |

7X2.5 |

re |

2.5 |

15.1 |

200.0 |

400.0 |

|

12 |

7X4 |

re |

4 |

18.1 |

316.0 |

580.0 |

|

16 |

10X1.5 |

re |

2.5 |

17.2 |

177.0 |

420.0 |

|

14 |

10X2.5 |

re |

4 |

18.9 |

287.0 |

550.0 |

|

16 |

12X1.5 |

re |

2.5 |

18.4 |

204.0 |

460.0 |

|

14 |

12X2.5 |

re |

4 |

19.2 |

335.0 |

610.0 |

|

12 |

12X4 |

re |

6 |

22.6 |

528.0 |

910.0 |

|

16 |

16X1.5 |

re |

4 |

20.0 |

275.0 |

686.0 |

|

14 |

16X2.5 |

re |

6 |

20.9 |

450.0 |

805.0 |

|

16 |

21X1.5 |

re |

6 |

22.6 |

370.0 |

766.0 |

|

14 |

21X2.5 |

re |

6 |

25.2 |

572.0 |

1015.0 |

|

16 |

24X1.5 |

re |

6 |

23.2 |

412.0 |

800.0 |

|

14 |

24X2.5 |

re |

10 |

26.1 |

695.0 |

1100.0 |

|

16 |

30X1.5 |

re |

6 |

24.3 |

500.0 |

930.0 |

|

14 |

30X2.5 |

re |

10 |

28.0 |

842.0 |

1290.0 |