| Application and Description | The cables are used for applications witd medium mechanical stresses and sharp bending in one place. They are suitable for use in dry, damp and wet rooms as power and control cable, especially on hoisting equipment, handling systems, machine tools, etc. |

| Standard and Approval | HD 359 S3, BS EN 50214, DIN VDE 0281 part 404, IEC 60332-1, CSA C22.2 N° 49, UL 62, UL 62 |

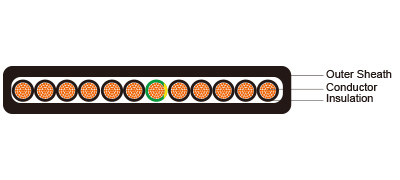

| Cable Construction | - Fine bare or tinned copper strands - Strands to VDE-0295 Class-5, IEC 60228 Class-5 - PVC compound insulation T12 to VDE 0207 part 4 - Color coded to VDE-0293-308 - PVC compound outer jacket TM2 to VDE 0207 part 5 |

| Technical Characteristics | -Working voltage: H05VVH6-F : 300/500 V H07VVH6-F: 450/700 V -Test voltage: H05VVH6-F : 2 KV H07VVH6-F: 2.5 KV -Bending radius: 10 × cable Ø -Flexing temperature: - 5º C to + 70º C -Static temperature :-40º C to +70º C -Flame retardant: test class B according to VDE 0472 part 804, IEC 60332-1 -Insulation resistance: 20 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

NOMINAL THICKNESS OF INSULATIONMM |

NOMINAL THICKNESS OF SHEATHMM |

NOMINAL OVERALL DIAMETERMM |

NOMINAL COPPER WEIGHTKG/KM |

NOMINAL WEIGHTKG/KM |

|

H05VVH6-F |

||||||

|

18(24/32) |

4 x 0.75 |

1.2 |

0.6 |

4.2 x 12.6 |

29 |

90 |

|

18(24/32) |

8x 0.75 |

1.2 |

0.6 |

4.2 x 23.2 |

58 |

175 |

|

18(24/32) |

12x 0.75 |

1.2 |

0.6 |

4.2 x 33.8 |

86 |

260 |

|

18(24/32) |

18x 0.75 |

1.2 |

0.6 |

4.2 x 50.2 |

130 |

380 |

|

18(24/32) |

24x 0.75 |

1.2 |

0.6 |

4.2 x 65.6 |

172 |

490 |

|

17(32/32) |

4 x 1.00 |

1.4 |

0.7 |

4.4 x 13.4 |

38 |

105 |

|

17(32/32) |

5×1.00 |

1.4 |

0.7 |

4.4 x 15.5 |

48 |

120 |

|

17(32/32) |

8 x 1.00 |

1.4 |

0.7 |

4.4 x 24.8 |

77 |

205 |

|

17(32/32) |

12x 1.00 |

1.4 |

0.7 |

4.4 x 36.2 |

115 |

300 |

|

17(32/32) |

18x 1.00 |

1.4 |

0.7 |

4.4 x 53.8 |

208 |

45 |

|

17(32/32) |

24x 1.00 |

1.4 |

0.7 |

4.4 x 70.4 |

230 |

590 |

|

H07VVH6-F |

||||||

|

16(30/30) |

4 x1.5 |

1.5 |

0.8 |

5.1 x 14.8 |

130 |

58 |

|

16(30/30) |

5 x1.5 |

1.5 |

0.8 |

5.1 x 17.7 |

158 |

72 |

|

16(30/30) |

7 x1.5 |

1.5 |

0.8 |

5.1 x 25.2 |

223 |

101 |

|

16(30/30) |

8 x1.5 |

1.5 |

0.8 |

5.1 x 27.3 |

245 |

115 |

|

16(30/30) |

10 x1.5 |

1.5 |

0.8 |

5.1 x 33.9 |

304 |

144 |

|

16(30/30) |

12 x1.5 |

1.5 |

0.8 |

5.1 x 40.5 |

365 |

173 |

|

16(30/30) |

18 x1.5 |

1.5 |

0.8 |

6.1 x 61.4 |

628 |

259 |

|

16(30/30) |

24 x1.5 |

1.5 |

0.8 |

5.1 x 83.0 |

820 |

346 |

|

14(30/50) |

4 x2.5 |

1.9 |

0.8 |

5.8 x 18.1 |

192 |

96 |

|

14(30/50) |

5 x2.5 |

1.9 |

0.8 |

5.8 x 21.6 |

248 |

120 |

|

14(30/50) |

7 x2.5 |

1.9 |

0.8 |

5.8 x 31.7 |

336 |

168 |

|

14(30/50) |

8 x2.5 |

1.9 |

0.8 |

5.8 x 33.7 |

368 |

192 |

|

14(30/50) |

10 x2.5 |

1.9 |

0.8 |

5.8 x 42.6 |

515 |

240 |

|

14(30/50) |

12 x2.5 |

1.9 |

0.8 |

5.8 x 49.5 |

545 |

288 |

|

14(30/50) |

24 x2.5 |

1.9 |

0.8 |

5.8 x 102.0 |

1220 |

480 |

|

12(56/28) |

4 x4 |

2.5 |

0.8 |

6.7 x 20.1 |

154 |

271 |

|

12(56/28) |

5 x4 |

2.5 |

0.8 |

6.9 x 26.0 |

192 |

280 |

|

12(56/28) |

7 x4 |

2.5 |

0.8 |

6.7 x 35.5 |

269 |

475 |

|

10(84/28) |

4 x6 |

3.0 |

0.8 |

7.2 x 22.4 |

230 |

359 |

|

10(84/28) |

5 x6 |

3.0 |

0.8 |

7.4 x 31.0 |

288 |

530 |

|

10(84/28) |

7 x6 |

3.0 |

0.8 |

7.4 x 43.0 |

403 |

750 |

|

8(80/26) |

4 x10 |

4.0 |

1.0 |

9.2 x 28.7 |

384 |

707 |

|

8(80/26) |

5 x10 |

4.0 |

1.0 |

11.0 x 37.5 |

480 |

1120 |

|

6(128/26) |

4 x16 |

5.6 |

1.0 |

11.1 x 35.1 |

614 |

838 |

|

6(128/26) |

5 x16 |

5.6 |

1.0 |

11.2 x 43.5 |

768 |

1180 |