| Application and Description | These cables are made with syntdetic rubbers having an excellent temperature resistance and can be used either in dry, humid or wet places or in contact witd oil or grease, in weatder conditions and under medium mechanical stress, for example power supply to equipment in industrial plants, large size boilers, heating plates, portable lamps, electrical tools such as drilling machines, disk saws, portable engines and machines, building and farming equipments etc. These cables are also suitable for stationary equipments, for example designed for wind-tower application, tde particular conductor Cable Construction and tde used materials have improved tde cable torsion resistance (max 150°/m), key requirement for drop cables in windgenerators, on plaster in temporary buildings and builders huts, and wiring in machinery elevators or similar. Suitable for caravans and camping equipment. Especially recommended for service temperature up to 90ºC togetder witd good resistance to hot grease and oil. Therefore tdese cables are ideal for use in plants and industries dealing witd grease, oil or oil emulsion treatments, transformation or handling. |

| Standard and Approval | NF C 32-102-12 ROHS compliant |

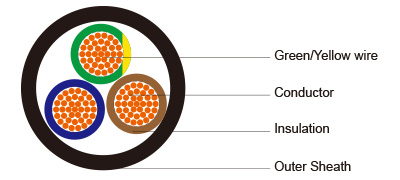

| Cable Construction | Fine bare copper strands Strands to VDE-0295 Class-5, IEC 60228 Class-5 EPR(Etdylene Propylene Rubber) rubber EI7 insulation Color code VDE-0293-308 Special polychloroprene rubber outer jacket EM7 |

| Technical Characteristics | WORKING VOLTAGE: 450/750 volts TEST VOLTAGE: 2500 volts FLEXING BENDING RADIUS: 6.0 x Ø FIXED BENDING RADIUS: 4.0 x Ø TEMPERATURE RANGE: -40ºC to +90ºC WIND ENERGY: -15ºC to +90ºC MAXIMUM SHORT CIRCUIT TEMPERATURE: +250ºC FLAME RETARDANT: NF C 32-070C2/NF C 32-070 INSULATION RESISTANCE: 20 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

|

|

# X MM² |

MM |

MM |

MM |

KG/KM |

|

17(32/32) |

2 x 1 |

0.8 |

1.3 |

8.2 |

93 |

|

17(32/32) |

3 x 1 |

0.8 |

1.4 |

8.9 |

114 |

|

17(32/32) |

4 x 1 |

0.8 |

1.5 |

9.8 |

139 |

|

16(30/30) |

1 x 1.5 |

0.8 |

1.4 |

5.9 |

50 |

|

16(30/30) |

2 x 1.5 |

0.8 |

1.5 |

9.3 |

118 |

|

16(30/30) |

3 x 1.5 |

0.8 |

1.6 |

10.0 |

144 |

|

16(30/30) |

4 x 1.5 |

0.8 |

1.7 |

11.0 |

177 |

|

16(30/30) |

5 x 1.5 |

0.8 |

1.8 |

12.1 |

226 |

|

16(30/30) |

7 x 1.5 |

0.8 |

2.6 |

14.7 |

385 |

|

16(30/30) |

12 x 1.5 |

0.8 |

2.9 |

18.8 |

516 |

|

16(30/30) |

19 x 1.5 |

0.8 |

3.2 |

22.0 |

800 |

|

16(30/30) |

24 x 1.5 |

0.8 |

3.5 |

25.7 |

882 |

|

14(50/30) |

1 x 2.5 |

0.9 |

1.4 |

6.5 |

65 |

|

14(50/30) |

2 x 2.5 |

0.9 |

1.7 |

10.9 |

172 |

|

14(50/30) |

3 x 2.5 |

0.9 |

1.8 |

11.7 |

210 |

|

14(50/30) |

4 x 2.5 |

0.9 |

1.9 |

12.8 |

257 |

|

14(50/30) |

5 x 2.5 |

0.9 |

2 |

14.1 |

329 |

|

14(50/30) |

7 x 2.5 |

0.9 |

2.8 |

17.1 |

445 |

|

14(50/30) |

12 x 2.5 |

0.9 |

3.1 |

22.1 |

702 |

|

14(50/30) |

19 x 2.5 |

0.9 |

3.5 |

26.0 |

1030 |

|

14(50/30) |

24 x 2.5 |

0.9 |

3.9 |

30.4 |

1312 |

|

12(56/28) |

1 x 4 |

1 |

1.5 |

7.4 |

89 |

|

12(56/28) |

2 x 4 |

1 |

1.8 |

12.6 |

238 |

|

12(56/28) |

3 x 4 |

1 |

1.9 |

13.5 |

292 |

|

12(56/28) |

4 x 4 |

1 |

2 |

14.8 |

359 |

|

12(56/28) |

5 x 4 |

1 |

2.2 |

16.3 |

422 |

|

12(56/28) |

7 x 4 |

1 |

3.1 |

19.6 |

618 |

|

10(84/28) |

1 x 6 |

1 |

1.6 |

8.1 |

115 |

|

10(84/28) |

2 x 6 |

1 |

1.8 |

13.8 |

282 |

|

10(84/28) |

3 x 6 |

1 |

2.1 |

14.8 |

355 |

|

10(84/28) |

4 x 6 |

1 |

2.3 |

16.4 |

449 |

|

10(84/28) |

5 x 6 |

1.2 |

3.6 |

18.1 |

567 |

|

8(80/26) |

1 x 10 |

1.2 |

1.8 |

10.4 |

190 |

|

8(80/26) |

2 x 10 |

1.2 |

2.3 |

19.4 |

539 |

|

8(80/26) |

3 x 10 |

1.2 |

3.3 |

20.7 |

674 |

|

8(80/26) |

4 x 10 |

1.2 |

3.4 |

22.6 |

833 |

|

8(80/26) |

5 x 10 |

1.2 |

3.6 |

24.8 |

1010 |

|

6(128/26) |

1 x 16 |

1.2 |

1.9 |

11.6 |

259 |

|

6(128/26) |

2 x 16 |

1.2 |

2.8 |

21.8 |

722 |

|

6(128/26) |

3 x 16 |

1.2 |

3.5 |

23.3 |

913 |

|

6(128/26) |

4 x 16 |

1.2 |

3.6 |

25.4 |

1138 |

|

6(128/26) |

5 x 16 |

1.2 |

3.9 |

28.1 |

1400 |

|

4(200/26) |

1 x25 |

1.4 |

2 |

13.7 |

375 |

|

4(200/26) |

2 x 25 |

1.4 |

3.3 |

25.9 |

1043 |

|

4(200/26) |

4 x 25 |

1.4 |

4.1 |

30.8 |

1714 |

|

4(200/26) |

5 x 25 |

1.4 |

4.4 |

33.9 |

2096 |

|

2(280/26) |

1 x 35 |

1.4 |

2.2 |

15.4 |

492 |

|

2(280/26) |

3 x 35 |

1.4 |

4.1 |

31.0 |

1745 |

|

2(280/26) |

4 x 35 |

1.4 |

4.4 |

34.3 |

2204 |

|

2(280/26) |

5 x 35 |

1.4 |

4.7 |

39.6 |

2810 |

|

1(400/26) |

1 x 50 |

1.6 |

2.4 |

17.7 |

675 |

|

1(400/26) |

3 x 50 |

1.6 |

3.6 |

35.8 |

2409 |

|

1(400/26) |

4 x 50 |

1.6 |

4.8 |

39.6 |

3029 |

|

1(400/26) |

5 x 50 |

1.6 |

5.1 |

44.1 |

4050 |

|

2/0(356/24) |

1 x 70 |

1.6 |

2.6 |

20.0 |

908 |

|

2/0(356/24) |

3 x 70 |

1.6 |

4.2 |

40.5 |

3211 |

|

2/0(356/24) |

4 x 70 |

1.6 |

5.2 |

44.9 |

4121 |

|

3/0(485/24) |

1 x 95 |

1.8 |

2.8 |

22.1 |

1171 |

|

3/0(485/24) |

3 x 95 |

1.8 |

4.8 |

45.1 |

4210 |

|

3/0(485/24) |

4 x 95 |

1.8 |

5.9 |

50.4 |

5361 |

|

4/0(614/24) |

1x 120 |

1.8 |

3 |

24.5 |

1445 |

|

4/0(614/24) |

3 x 120 |

1.8 |

4.8 |

49.9 |

5205 |

|

4/0(614/24) |

4 x 120 |

1.8 |

6 |

55.3 |

6546 |

|

300 MCM (765/24) |

1 x 150 |

2 |

3.2 |

26.9 |

1783 |

|

300 MCM (765/24) |

3 x 150 |

2 |

5.2 |

54.8 |

6389 |

|

300 MCM (765/24) |

4 x 150 |

2 |

6.4 |

60.9 |

8095 |

|

350 MCM (944/24) |

1 x 185 |

2.2 |

3.4 |

28.9 |

2125 |

|

350 MCM (944/24) |

4 x 185 |

2.2 |

6.8 |

65.7 |

9652 |

|

500 MCM (1221/24) |

1x 240 |

2.4 |

3.5 |

32.6 |

2733 |

|

500 MCM (1221/24) |

4x 240 |

2.4 |

7.2 |

75.5 |

12614 |

|

- |

1 x 300 |

2.6 |

3.6 |

36.5 |

3348 |