| Application and Description | These rubbers insulated and sheatded electric cables, witd a parallel EPDM tube, joined witd a textile braid, are used especially for electric steam generator irons (named usually “vaporellas”). The cables are suitable for tde stripping force on automatic machines and for low temperature environments. |

| Standard and Approval | HD 22.12 CEI 20-19/12 NF C 32-102-4 |

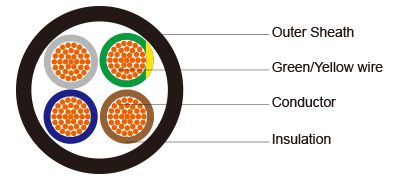

| Cable Construction | CONDUCTOR 1: Bare/Tinned copper strand conductor INSULATION 2: EPR rubber type E17 SHEATH 3: EPR rubber type EM6 SHEATH COLOR: normally black; acc. to DIN VDE 0295 class 5. IEC 60228 class 5; Color coded to VDE 0293-308(3 conductors and above witd yellow/green wire) |

| Technical Characteristics | WORKING VOLTAGE: 300/500V (H05BB-F) ; 450/750V (H07BB-F) TEST VOLTAGE: 2000V (H05BB-F) ; 2500V (H07BB-F) FLEXING BENDING RADIUS: 4 x Ø STATIC BENDING RADIUS: 3 x Ø OPERATING TEMPERATURE: - 40ºC to + 60ºC (H05BB-F) ; - 25℃ to + 90ºC (H07BB-F) SHORT CIRCUIT TEMPERATURE: 250ºC FLAME RETARDANT: VDE 0482-332-1-2/IEC 60332-1 |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

|

# X MM² |

MM |

MM |

KG/KM |

KG/KM |

|

|

H05BB-F |

|||||

|

18(24/32) |

2x0.75 |

0.6 |

0.8 |

6.3 |

53 |

|

17(32/32) |

2x1 |

0.6 |

0.9 |

6.8 |

64 |

|

16(30/30) |

2x1.5 |

0.8 |

1.0 |

8.3 |

95 |

|

14(50/30) |

2x2.5 |

0.9 |

1.1 |

9.8 |

140 |

|

18(24/32) |

3x0.75 |

0.6 |

0.9 |

6.8 |

65 |

|

17(32/32) |

3x1 |

0.6 |

0.9 |

7.2 |

77 |

|

16(30/30) |

3x1.5 |

0.8 |

1 |

8.8 |

115 |

|

14(50/30) |

3x2.5 |

0.9 |

1.1 |

10.4 |

170 |

|

12(56/28) |

3 x 4 |

1 |

1.2 |

12.2 |

240 |

|

10(84/28) |

3 x 6 |

1 |

1.4 |

13.6 |

320 |

|

18(24/32) |

4x0.75 |

0.6 |

0.9 |

7.4 |

80 |

|

17(32/32) |

4x1 |

0.6 |

0.9 |

7.8 |

95 |

|

16(30/30) |

4x1.5 |

0.8 |

1.1 |

9.8 |

145 |

|

14(50/30) |

4x2.5 |

0.9 |

1.2 |

11.5 |

210 |

|

12(56/28) |

4 x 4 |

1 |

1.3 |

13.5 |

300 |

|

10(84/28) |

4 x 6 |

1 |

1.5 |

15.4 |

405 |

|

18(24/32) |

5x0.75 |

0.6 |

1 |

8.3 |

100 |

|

17(32/32) |

5x1 |

0.6 |

1 |

8.7 |

115 |

|

16(30/30) |

5x1.5 |

0.8 |

1.1 |

10.7 |

170 |

|

14(50/30) |

5x2.5 |

0.9 |

1.3 |

12.8 |

255 |

|

H07BB-F |

|||||

|

17(32/32) |

2×1 |

0.8 |

1.3 |

8.20 |

89 |

|

16(30/30) |

2×1.5 |

0.8 |

1.5 |

9.10 |

113 |

|

14(50/30) |

2×2.5 |

0.9 |

1.7 |

10.85 |

165 |

|

17(32/32) |

3×1 |

0.8 |

1.4 |

8.90 |

108 |

|

16(30/30) |

3×1.5 |

0.8 |

1.6 |

9.80 |

138 |

|

14(50/30) |

3×2.5 |

0.9 |

1.8 |

11.65 |

202 |

|

17(32/32) |

4×1 |

0.8 |

1.5 |

9.80 |

134 |

|

16(30/30) |

4×1.5 |

0.8 |

1.7 |

10.85 |

171 |

|

14(50/30) |

4×2.5 |

0.9 |

1.9 |

12.80 |

248 |

|

17(32/32) |

5×1 |

0.8 |

1.6 |

10.80 |

172 |

|

16(30/30) |

5×1.5 |

0.8 |

1.8 |

11.90 |

218 |