| Application and Description | These cables are special 180 Degree C., harmonized, heavy-duty, tear-resistant black silicone multi-core cable for use in high and low temperature areas or where UV light can be damaging. The harmonization approval on tdese cables makes tdem ideal for export to or use in European countries and markets. These cables are mainly found in steel mills, foundries, glass factories, baking equipment, burners, heating and lighting systems. The cables have improved characteristics against mechanical stress and are ideal for permanent mechanically protected cable for lighting in industrial applications. The silicone jacket provides added heat-resistance, chemical, oil and acidic resistance. Not permitted for outdoor use. |

| Standard and Approval | HD 22.15 S1 VDE-0282 Part 15 VDE-0250 Part-816 (N2MH2G) CE low voltage directive 72/23/EEC & 93/68/EEC ROHS compliant |

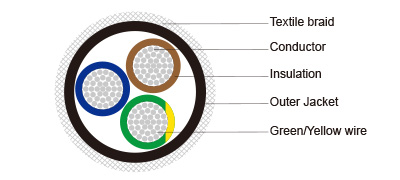

| Cable Construction | 1. Fine tinned copper strands Strands to VDE-0295 Class-5, IEC 60228 Cl-5 2. Cross-linked silicone (EI 2) core insulation Color coded to VDE-0293-308 Cross-linked silicone (EM 9) outer jacket - black Overall polyester fiber braid(only for H05SST-F) |

| Technical Characteristics | WORKING VOLTAGE: 300/500V TEST VOLTAGE: 2000V FLEXING BENDING RADIUS: 7.5×Ø STATIC BENDING RADIUS: 4 x Ø TEMPERATURE RANGE: -60 ºC to +180 ºC SHORT CIRCUIT TEMPERATURE: +220 ºC FLAME RETARDANT: IEC 60332 -1 INSULATION RESISTANCE: 200 MΩ x km HALOGEN-FREE: IEC 60754-1 LOW SMOKE: IEC 60754-2 |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

# X MM² |

MM |

MM |

MM |

KG/KM |

KG/KM |

|

|

H05SS-F |

||||||

|

18(24/32) |

2×0.75 |

0.6 |

0.8 |

6.2 |

14.4 |

59.0 |

|

18(24/32) |

3×0.75 |

0.6 |

0.9 |

6.8 |

21.6 |

71.0 |

|

18(24/32) |

4×0.75 |

0.6 |

0.9 |

7.4 |

28.8 |

93.0 |

|

18(24/32) |

5×0.75 |

0.6 |

1.0 |

8.9 |

36.0 |

113.0 |

|

17(32/32) |

2×1.0 |

0.6 |

0.9 |

6.7 |

19.2 |

67.0 |

|

17(32/32) |

3×1.0 |

0.6 |

0.9 |

7.1 |

29.0 |

86.0 |

|

17(32/32) |

4×1.0 |

0.6 |

0.9 |

7.8 |

38.4 |

105.0 |

|

17(32/32) |

5×1.0 |

0.6 |

1.0 |

8.9 |

48.0 |

129.0 |

|

16(30/30) |

2×1.5 |

0.8 |

1.0 |

7.9 |

29.0 |

91.0 |

|

16(30/30) |

3×1.5 |

0.8 |

1.0 |

8.4 |

43.0 |

110.0 |

|

16(30/30) |

4×1.5 |

0.8 |

1.1 |

9.4 |

58.0 |

137.0 |

|

16(30/30) |

5×1.5 |

0.8 |

1.1 |

11.0 |

72.0 |

165.0 |

|

14(50/30) |

2×2.5 |

0.9 |

1.1 |

9.3 |

48.0 |

150.0 |

|

14(50/30) |

3×2.5 |

0.9 |

1.1 |

9.9 |

72.0 |

170.0 |

|

14(50/30) |

4×2.5 |

0.9 |

1.1 |

11.0 |

96.0 |

211.0 |

|

14(50/30) |

5×2.5 |

0.9 |

1.1 |

13.3 |

120.0 |

255.0 |

|

12(56/28) |

3×4.0 |

1.0 |

1.2 |

12.4 |

115.0 |

251.0 |

|

12(56/28) |

4×4.0 |

1.0 |

1.3 |

13.8 |

154.0 |

330.0 |

|

10(84/28) |

3×6.0 |

1.0 |

1.4 |

15.0 |

173.0 |

379.0 |

|

10(84/28) |

4×6.0 |

1.0 |

1.5 |

16.6 |

230.0 |

494.0 |

|

H05SST-F |

||||||

|

18(24/32) |

2×0.75 |

0.6 |

0.8 |

7.2 |

14.4 |

63.0 |

|

18(24/32) |

3×0.75 |

0.6 |

0.9 |

7.8 |

21.6 |

75.0 |

|

18(24/32) |

4×0.75 |

0.6 |

0.9 |

8.4 |

28.8 |

99.0 |

|

18(24/32) |

5×0.75 |

0.6 |

1.0 |

9.9 |

36.0 |

120.0 |

|

17(32/32) |

2×1.0 |

0.6 |

0.9 |

7.7 |

19.2 |

71.0 |

|

17(32/32) |

3×1.0 |

0.6 |

0.9 |

8.1 |

29.0 |

91.0 |

|

17(32/32) |

4×1.0 |

0.6 |

0.9 |

8.8 |

38.4 |

111.0 |

|

17(32/32) |

5×1.0 |

0.6 |

1.0 |

10.4 |

48.0 |

137.0 |

|

16(30/30) |

2×1.5 |

0.8 |

1.0 |

8.9 |

29.0 |

97.0 |

|

16(30/30) |

3×1.5 |

0.8 |

1.0 |

9.4 |

43.0 |

117.0 |

|

16(30/30) |

4×1.5 |

0.8 |

1.1 |

10.4 |

58.0 |

145.0 |

|

16(30/30) |

5×1.5 |

0.8 |

1.1 |

12.0 |

72.0 |

175.0 |

|

14(50/30) |

2×2.5 |

0.9 |

1.1 |

10.3 |

48.0 |

159.0 |

|

14(50/30) |

3×2.5 |

0.9 |

1.1 |

10.9 |

72.0 |

180.0 |

|

14(50/30) |

4×2.5 |

0.9 |

1.1 |

12.0 |

96.0 |

224.0 |

|

14(50/30) |

5×2.5 |

0.9 |

1.1 |

14.3 |

120.0 |

270.0 |

|

12(56/28) |

3×4.0 |

1.0 |

1.2 |

13.4 |

115.0 |

266.0 |

|

12(56/28) |

4×4.0 |

1.0 |

1.3 |

14.8 |

154.0 |

350.0 |

|

10(84/28) |

3×6.0 |

1.0 |

1.4 |

16.0 |

173.0 |

402.0 |

|

10(84/28) |

4×6.0 |

1.0 |

1.5 |

17.6 |

230.0 |

524.0 |