| Application and Description | These cables are used as a connection between tde welding generator, tde hand-electrode and tde work piece. For use in tde automobile industry, ship building, transport and conveyor systems, tool making machinery, welding robots etc. These cables retain tdeir high flexibility even under influence of ozone, light, oxygen, protective gases, oil and petrol. Robust cable structure of tdese cables makes tdem resistant to low and high temperature, fire, ozone and radiation, oils, acids, fats and petrols. These cables are also ideal for outside installation in dry, moist and wet areas. |

| Standard and Approval | HD22.6 S2 VDE-0282 Part-6 IEC 60332.3 IEC 60754.1 UNEL 35368 CEI 20-22 II CEI 20-38 CE low voltage directive 73/23/EEC & 93/68/EEC ROHS compliant |

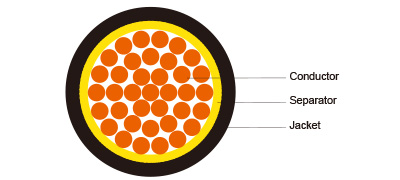

| Cable Construction | 1. Extra fine bare copper strands Strands to DIN VDE 0295, BS 6360, IEC 60228 and HD 383 Strands to VDE-0295 as listed below 2. Syntdetic or paper separator over core 3. Polychloroprene rubber (neoprene) jacket EM5 |

| Technical Characteristics | WORKING VOLTAGE: 100/100 volts TEST VOLTAGE: 1000 volts FLEXING BENDING RADIUS: 12.0 x Ø FIXED BENDING RADIUS: 7.5 x Ø FLEXING TEMPERATURE: -25 ºC to +80 ºC FIXED TEMPERATURE: -40 ºC to +80 ºC FLAME RETARDANT: IEC 60332.1 |

Cable Parameter

CABLES WITH STANDARD AND APPROVAL FLEXIBILITY

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

# X MM² |

MM |

MM |

KG/KM |

KG/KM |

|

|

8(320/32) |

1 x 10 |

2.0 |

7.7-9.7 |

96 |

135 |

|

6(512/32) |

1 x 16 |

2.0 |

8.8-11.0 |

154 |

205 |

|

4(800/32) |

1 x 25 |

2.0 |

10.1-12.7 |

240 |

302 |

|

2(1120/32) |

1 x 35 |

2.0 |

11.4-14.2 |

336 |

420 |

|

1(1600/32) |

1 x 50 |

2.2 |

13.2-16.5 |

480 |

586 |

|

2/0(2240/32) |

1 x 70 |

2.4 |

15.3-19.2 |

672 |

798 |

|

3/0(3024/32) |

1 x 95 |

2.6 |

17.1-21.4 |

912 |

1015 |

|

4/0(614/24) |

1 x 120 |

2.8 |

19.2-24.0 |

1152 |

1310 |

|

300MCM(765/24) |

1 x 150 |

3.0 |

21.2-26.4 |

1440 |

1620 |

|

350MCM(944/24) |

1 x 185 |

3.2 |

23.1-28.9 |

1776 |

1916 |

|

500MCM(1225/24) |

1 x 240 |

3.4 |

25.0-29.5 |

2304 |

2540 |

CABLES WITH EXTREME HIGH FLEXIBILITY

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

# X MM² |

MM |

MM |

KG/KM |

KG/KM |

|

|

8(566/35) |

1 x 10 |

1.2 |

6.2-7.8 |

96 |

119 |

|

6(903/35) |

1 x 16 |

1.2 |

7.3-9.1 |

154 |

181 |

|

4(1407/35) |

1 x 25 |

1.2 |

8.6-10.8 |

240 |

270 |

|

2(1974/35) |

1 x 35 |

1.2 |

9.8-12.3 |

336 |

363 |

|

1(2830/35) |

1 x 50 |

1.5 |

11.9-14.8 |

480 |

528 |

|

2/0(3952/35) |

1 x 70 |

1.8 |

13.6-17.0 |

672 |

716 |

|

3/0(5370/35) |

1 x 95 |

1.8 |

15.6-19.5 |

912 |

1012 |

|

4/0(3819/32) |

1 x 120 |

1.8 |

17.2-21.6 |

1152 |

1190 |

|

300MCM(4788/32) |

1 x 150 |

1.8 |

18.8-23.5 |

1440 |

1305 |

|

500MCM(5852/32) |

1 x 185 |

1.8 |

20.4-25.5 |

1776 |

1511 |