Multicores double steel tape armoured low voltage IEC60502 - 1 Power Cable

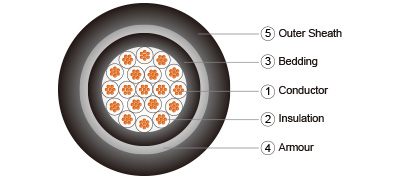

CU/PVC/PVC/DSTA/PVC (Multi - Cores)

PVC Insulated, PVC Bedded, Double Steel Tape Armoured, PVC Sheathed Cable

Application

These power cable for fixed installations such as distribution networks or industrial installations.

Such as Plant engineering; Industrial machinery; Heating and air-conditioning systems; Power stations; Stage applications etc.

Armoured cable suitable for direct burial.

Construction

Conductor: Plain annealed copper, class1 solid or class 2 stranded acc. to IEC 60228.

Flexible class 5 or tinned conductor could be offer upon request.

Insulation: Polyviny chloride (PVC) compound as per IEC 60502-1.

Insulation Color Code:

| Number of Cores | Color Code to IEC 60502-1 | Color Code to BS 5467 |

| 6 and above | White with Black Numbering or Others |

White with Black Numbering or Others |

Assembly: Cores cabled together with PP filler and covered with non-woven tape.

Bedding: Polyvinyl choride (PVC) compound type ST1 (80°C), ST2 (90°C) of IEC 60502-1.

Bedding Colour: Black or other color as per customer request.

Armour: Double steel tape armoured (DSTA).

Outer Sheath: Polyvinyl choride (PVC) compound type ST1 (80°C), ST2 (90°C) of IEC 60502-1.

Outer Sheath Color: Black or other color as per customer request.

Electrical Characteristics

Recommended rated voltages U0

| Highest system voltage (Um) (kV) |

Rated voltage (U0) (kV) | |

| Categories A and B | Category C | |

| 1,2 | 0,6 | 0,6 |

Routine test voltages

| Rated voltage U0 (kV) | 0,6 |

| Test voltage (kV) | 3,5 |

Maximum conductor temperatures for different types of insulating compound

| Maximum conductor temperature (°C) | |

| Normal operation | Short-circuit (5 s maximum duration) |

| 70 | 160 |

Minimum Insulation Resistance at 20°C: 36.7 MΩ·km

Operating Temperature: -15°C to 70°C

Test Voltage: 3.5 kV for 5 minutes

Installation Refference

Min.Bending Radius (mm): 8 x cable overall diameter

Max.Pulling Tension (N/mm2): 70

Reference Standards

Design: IEC60502-1

Conductor: IEC60228, BS EN60228

Flame Retardancy: IEC 60332-1, BS EN60332-1

Dimension

| No.of Cores | Nominal Conductor Area (mm2) |

No. and Diameter of Wires (no./mm) |

Thickness of Insulation (mm) |

Thickness of Inner Sheath (mm) |

Thickness of Armour Tape (mm) |

Thickness of Outer Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 5 | 1.5 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 15 | 408 |

| 7 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 16 | 482 | |

| 10 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 19.2 | 636 | |

| 12 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 19.7 | 699 | |

| 19 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 22.4 | 944 | |

| 20 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 22.8 | 982 | |

| 24 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 25.5 | 1,149 | |

| 37 | 7/0.53 | 0.8 | 1 | 0.2 | 1.8 | 28.7 | 1,560 | |

| 5 | 2.5 | 7/0.67 | 0.8 | 1 | 0.2 | 1.8 | 16.1 | 491 |

| 7 | 7/0.67 | 0.8 | 1 | 0.2 | 1.8 | 17.2 | 591 | |

| 10 | 7/0.67 | 0.8 | 1 | 0.2 | 1.8 | 20.8 | 788 | |

| 12 | 7/0.67 | 0.8 | 1 | 0.2 | 1.8 | 21.4 | 875 | |

| 19 | 7/0.67 | 0.8 | 1 | 0.2 | 1.8 | 24.5 | 1,207 | |

| 20 | 7/0.67 | 0.8 | 1 | 0.2 | 1.8 | 25 | 1,257 | |

| 24 | 7/0.67 | 0.8 | 1 | 0.2 | 1.8 | 28.1 | 1,478 | |

| 37 | 7/0.67 | 0.8 | 1.2 | 0.2 | 1.9 | 32.3 | 2,096 | |

| 5 | 4 | 7/0.85 | 1 | 1 | 0.2 | 1.8 | 18.7 | 663 |

| 7 | 7/0.85 | 1 | 1 | 0.2 | 1.8 | 20.1 | 813 | |

| 10 | 7/0.85 | 1 | 1 | 0.2 | 1.8 | 24.6 | 1,100 | |

| 12 | 7/0.85 | 1 | 1 | 0.2 | 1.8 | 25.3 | 1,235 | |

| 19 | 7/0.85 | 1 | 1 | 0.2 | 1.8 | 29.2 | 1,740 | |

| 20 | 7/0.85 | 1 | 1 | 0.2 | 1.9 | 30.1 | 1,831 | |

| 24 | 7/0.85 | 1 | 1.2 | 0.2 | 2 | 34.5 | 2,217 | |

| 37 | 7/0.85 | 1 | 1.2 | 0.5 | 2.2 | 40.7 | 3,690 |