| Standards: | JISC 3410-1999 IEC 60332-1 IEC 60332-3 Cat.A(for FA-type) |

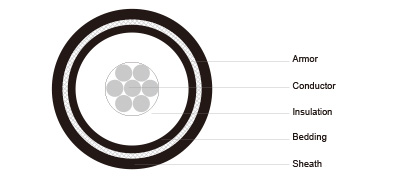

CABLE CONSTRUCTION

| Conductor | S | Tinned annealed stranded copper, class 2 according to IEC 60228 |

| Insulation | P | 85°C EPR as per JIS C 3401 |

| Bedding | Y | PVC as per JIS C 3401 |

| Armor | C (CB) | Galvanized steel wire braid(-C TYPE) or copper alloy wire braid(-CB TYPE) |

| Sheath | Y | PVC as per JIS C 3401 |

| Outer sheath color | Black |

Cable Parameter

| Conductor | Thick. of insulation | Thick. of bedding | Dia. over bedding | Dia. of armor | (FA-) SPYC, SPYCB | ||||

| Size | Construction | O.D | Nominal overall dia. | Tolerance | Cable weight (Approx.) | ||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | Kg / Km |

| 1.5 | 7/0.53 | 1.59 | 1.0 | 1.0 | 5.9 | 0.3 | 7.2 | 0.4 | 100 |

| 2.5 | 7/0.67 | 2.01 | 1.0 | 1.0 | 6.3 | 0.3 | 7.8 | 0.4 | 120 |

| 4 | 7/0.85 | 2.55 | 1.0 | 1.0 | 6.9 | 0.3 | 8.2 | 0.4 | 140 |

| 6 | 7/1.04 | 3.12 | 1.0 | 1.0 | 7.4 | 0.3 | 8.7 | 0.4 | 170 |

| 10 | 7/1.35 | 4.05 | 1.0 | 1.1 | 8.6 | 0.3 | 9.9 | 0.4 | 225 |

| 16 | 7/1.70 | 5.1 | 1.0 | 1.1 | 9.6 | 0.3 | 10.9 | 0.4 | 300 |

| 25 | 7/2.14 | 6.42 | 1.2 | 1.2 | 11.5 | 0.3 | 12.8 | 0.5 | 425 |

| 35 | 7/2.52 | 7.56 | 1.2 | 1.2 | 12.7 | 0.3 | 14.0 | 0.6 | 535 |

| 50 | 19/1.78 | 8.9 | 1.4 | 1.3 | 14.6 | 0.3 | 15.9 | 0.6 | 695 |

| 70 | 19/2.14 | 10.7 | 1.6 | 1.4 | 17.2 | 0.3 | 18.5 | 0.7 | 960 |

| 95 | 19/2.52 | 12.6 | 1.6 | 1.5 | 19.3 | 0.3 | 20.6 | 0.8 | 1250 |

| 120 | 37/2.03 | 14.2 | 1.6 | 1.5 | 20.9 | 0.3 | 22.2 | 0.9 | 1510 |

| 150 | 37/2.25 | 15.8 | 1.8 | 1.6 | 23.1 | 0.3 | 24.4 | 1.0 | 1830 |

| 185 | 37/2.52 | 17.6 | 2.0 | 1.7 | 25.5 | 0.3 | 26.8 | 1.1 | 2250 |

| 240 | 61/2.25 | 20.3 | 2.2 | 1.8 | 28.8 | 0.3 | 30.1 | 1.2 | 2910 |

| 300 | 61/2.52 | 22..7 | 2.4 | 1.9 | 31.8 | 0.4 | 33.6 | 1.3 | 3680 |

(FA-)SPYCY, SPYCBY

| Conductor | Thick. of insulation | Thick. of bedding | Dia. over bedding | Dia. of armor | (FA-) SPYCY, SPYCBY | |||||

| Size | Construction | O.D | Thick.of Sheath | Nominal overall dia. | Tolerance | Cable weight (Approx.) | ||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | mm | Kg / Km |

| 1.5 | 7/0.53 | 1.59 | 1.0 | 1.0 | 5.9 | 0.3 | 0.8 | 9.0 | 0.4 | 135 |

| 2.5 | 7/0.67 | 2.01 | 1.0 | 1.0 | 6.3 | 0.3 | 0.8 | 9.4 | 0.4 | 150 |

| 4 | 7/0.85 | 2.55 | 1.0 | 1.0 | 6.9 | 0.3 | 0.8 | 10.0 | 0.4 | 175 |

| 6 | 7/1.04 | 3.12 | 1.0 | 1.0 | 7.4 | 0.3 | 0.8 | 10.5 | 0.4 | 205 |

| 10 | 7/1.35 | 4.05 | 1.0 | 1.1 | 8.6 | 0.3 | 0.8 | 11.7 | 0.5 | 270 |

| 16 | 7/1.70 | 5.1 | 1.0 | 1.1 | 9.6 | 0.3 | 0.9 | 12.9 | 0.5 | 350 |

| 25 | 7/2.14 | 6.42 | 1.2 | 1.2 | 11.5 | 0.3 | 0.9 | 14.8 | 0.6 | 485 |

| 35 | 7/2.52 | 7.56 | 1.2 | 1.2 | 12.7 | 0.3 | 1.0 | 16.2 | 0.6 | 605 |

| 50 | 19/1.78 | 8.9 | 1.4 | 1.3 | 14.6 | 0.3 | 1.0 | 18.1 | 0.7 | 775 |

| 70 | 19/2.14 | 10.7 | 1.6 | 1.4 | 17.2 | 0.3 | 1.1 | 20.9 | 0.8 | 1060 |

| 95 | 19/2.52 | 12.6 | 1.6 | 1.5 | 19.3 | 0.3 | 1.1 | 23.0 | 0.9 | 1360 |

| 120 | 37/2.03 | 14.2 | 1.6 | 1.5 | 20.9 | 0.3 | 1.2 | 24.8 | 1.0 | 1650 |

| 150 | 37/2.25 | 15.8 | 1.8 | 1.6 | 23.1 | 0.3 | 1.2 | 27.0 | 1.1 | 1980 |

| 185 | 37/2.52 | 17.6 | 2.0 | 1.7 | 25.5 | 0.3 | 1.3 | 29.6 | 1.2 | 2420 |

| 240 | 61/2.25 | 20.3 | 2.2 | 1.8 | 28.8 | 0.3 | 1.4 | 33.1 | 1.3 | 3110 |

| 300 | 61/2.52 | 22..7 | 2.4 | 1.9 | 31.8 | 0.4 | 1.4 | 36.6 | 1.5 | 3910 |