| Application: |

These elastomeric insulated cables are designed for fixed wiring in ships and on mobile offshore units, suitable for use in instrumentation, lighting and control circuits. |

| Standards: | BS 6883 IEC 60332-3A Flame retardant IEC 60754-1; IEC 60754-2 Corrosivity IEC 61034-2 Smoke density Cold bend and impact (-40°C) (on request) CSA C22.2 No. 38-95 (on request) |

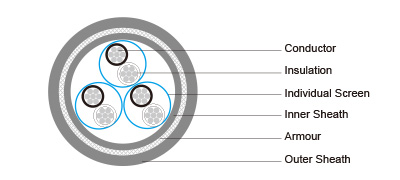

| Construction: | Conductor: Tinned copper wire stranded circular cl. 2 BS 6360/IEC 60228. Insulation: HF-EPR GP4 according to BS 7655 1.2. Lay-up: Pairs, triples, quads. Individual Screen: Aluminium/polyester tape + drain wire tinned copper. Inner Sheath: Halogen free thermosetting compound SW4 according to BS 7655 2.6 or reduced halogen thermosetting compound SW2 according to BS 7655 2.6. Armour: Galvanized steel wire braid. Tinned bronze wire braid can be offered upon request. Outer Sheath: Halogen free thermosetting compound SW4 according to BS 7655 2.6 or reduced halogen thermosetting compound SW2 according to BS 7655 2.6. |

| Mechanical and Thermal Properties: | Minimum Internal Bending Radius: 8×OD Temperature Range: -40℃ ~ +90℃ |

Dimensions and Weight

| Construction No. of cores×Cross section(mm²) |

Nominal Insulation Thickness mm |

Nominal Inner Sheath Thickness mm |

Minimum Diameter Over Inner Sheath mm |

Maximum Diameter Over Inner Sheath mm |

Nominal Armour Wire Diameter mm |

Nominal Outer Sheath Thickness mm |

Minimum Overall Diameter mm |

Maximum Overall Diameter mm |

Approx. Weight kg/km |

| Multipair | |||||||||

| 1×2×0.75 | 0.8 | 1.0 | 7.3 | 9.0 | 0.3 | 1.2 | 11.1 | 12.9 | 250 |

| 3×2×0.75 | 0.8 | 1.2 | 12.6 | 14.5 | 0.3 | 1.4 | 16.7 | 19.0 | 440 |

| 7×2×0.75 | 0.8 | 1.4 | 16.9 | 19.0 | 0.3 | 1.6 | 21.4 | 24.3 | 730 |

| 12×2×0.75 | 0.8 | 1.6 | 21.3 | 23.7 | 0.3 | 1.8 | 26.1 | 29.2 | 1090 |

| 20×2×0.75 | 0.8 | 1.9 | 27.0 | 29.8 | 0.45 | 2.1 | 33.2 | 37.0 | 1750 |

| 27×2×0.75 | 0.8 | 2.0 | 30.8 | 33.9 | 0.45 | 2.3 | 37.3 | 41.3 | 2190 |

| 37×2×0.75 | 0.8 | 2.2 | 35.9 | 39.3 | 0.45 | 2.5 | 42.9 | 47.5 | 2780 |

| 1×2×1 | 0.8 | 1.0 | 7.7 | 9.5 | 0.3 | 1.2 | 11.5 | 13.4 | 260 |

| 3×2×1 | 0.8 | 1.3 | 13.5 | 15.5 | 0.3 | 1.4 | 17.6 | 20.0 | 490 |

| 7×2×1 | 0.8 | 1.4 | 18.0 | 20.1 | 0.3 | 1.6 | 22.5 | 25.4 | 810 |

| 12×2×1 | 0.8 | 1.7 | 22.8 | 25.4 | 0.45 | 1.9 | 28.6 | 31.8 | 1370 |

| 20×2×1 | 0.8 | 1.9 | 28.8 | 31.6 | 0.45 | 2.2 | 35.2 | 39.0 | 2010 |

| 27×2×1 | 0.8 | 2.1 | 32.8 | 36.0 | 0.45 | 2.4 | 39.5 | 44.0 | 2570 |

| 37×2×1 | 0.8 | 2.3 | 38.5 | 42.3 | 0.45 | 2.6 | 45.7 | 50.4 | 3290 |

| Multitriple | |||||||||

| 1×3×0.75 | 0.8 | 1.0 | 7.7 | 9.4 | 0.3 | 1.2 | 11.5 | 13.3 | 270 |

| 3×3×0.75 | 0.8 | 1.3 | 14.2 | 16.2 | 0.3 | 1.5 | 18.6 | 20.9 | 540 |

| 7×3×0.75 | 0.8 | 1.5 | 19.7 | 22.1 | 0.3 | 1.7 | 24.4 | 27.4 | 910 |

| 12×3×0.75 | 0.8 | 1.7 | 24.4 | 27.1 | 0.45 | 2.0 | 30.4 | 34.1 | 1500 |

| 1×3×1 | 0.8 | 1.1 | 8.4 | 10.1 | 0.3 | 1.2 | 12.1 | 14.0 | 290 |

| 3×3×1 | 0.8 | 1.3 | 15.0 | 17.2 | 0.3 | 1.5 | 19.4 | 22.3 | 600 |

| 7×3×1 | 0.8 | 1.5 | 21.0 | 23.5 | 0.3 | 1.7 | 25.7 | 28.8 | 1030 |

| 12×3×1 | 0.8 | 1.8 | 26.2 | 28.9 | 0.45 | 2.0 | 32.2 | 36.0 | 1740 |

| Multiquad | |||||||||

| 1×4×0.75 | 0.8 | 1.1 | 8.6 | 10.4 | 0.3 | 1.2 | 12.4 | 14.3 | 290 |

| 3×4×0.75 | 0.8 | 1.4 | 16.4 | 18.5 | 0.3 | 1.5 | 20.9 | 23.8 | 610 |

| 7×4×0.75 | 0.8 | 1.6 | 22.1 | 24.7 | 0.3 | 1.7 | 27.0 | 30.2 | 1060 |

| 1×4×1 | 0.8 | 1.1 | 9.1 | 10.9 | 0.3 | 1.2 | 12.9 | 14.8 | 330 |

| 3×4×1 | 0.8 | 1.4 | 17.5 | 19.6 | 0.3 | 1.6 | 22.0 | 24.9 | 680 |

| 7×4×1 | 0.8 | 1.6 | 23.6 | 26.2 | 0.45 | 1.8 | 29.4 | 32.0 | 1290 |