| Applications : | These cables are flame retardant, low smoke and halogen free, used for earthing and bonding services. |

| Standards : | IEC 60092-353; IEC 60092-359; IEC 60332-1; IEC 60332-3-22; IEC 60754-1,2; IEC 61034-1,2; NEK 606:2004 |

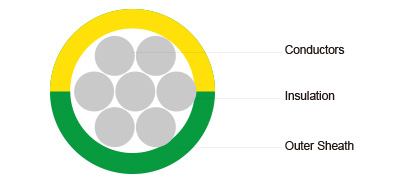

| Conductors : | Tinned annealed stranded copper to IEC 60228 class 2 or class 5. |

| Insulation : | Halogen free thermosetting compound, SHF2. When used as protective earth (PE) wire, the cables coloured yellow/green. When used as single wire, the cables coloured off-white, black, red or blue. |

Electrical Characteristics :

|

Nominal Cross Section Area |

mm² |

10 |

16 |

25 |

35 |

50 |

70 |

|

Nominal Conductor Diameter |

mm |

4 |

5.1 |

6.5 |

7.4 |

8.7 |

10.3 |

|

Maximum DC Resistant@20℃ |

Ω/km |

1.84 |

1.16 |

0.734 |

0.529 |

0.391 |

0.27 |

|

Continuous Current Rating@45℃1 Core |

A |

72 |

96 |

127 |

157 |

196 |

242 |

|

Short Circuit Current 1s |

A |

1430 |

2290 |

3580 |

5010 |

7150 |

10020 |

|

Operating Voltage |

KV |

0.6/1 |

0.6/1 |

0.6/1 |

0.6/1 |

0.6/1 |

0.6/1 |

Mechanical and Thermal Properties :

Bending Radius : 8×OD (during installation); 6×OD (fixed installed).

Temperature Range : -20℃ ~ +90℃.

Dimensions and Weight :

|

Construction No. of cores×Cross section (mm²) |

Nominal Insulation Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

|

1×10 |

2.0 |

8.2 |

160 |

|

1×16 |

2.1 |

9.4 |

230 |

|

1×25 |

2.4 |

11.3 |

350 |

|

1×35 |

2.4 |

12.4 |

450 |

|

1×50 |

2.7 |

14.4 |

600 |

|

1×70 |

3.0 |

16.7 |

840 |

|

1×95 |

3.0 |

18.6 |

1110 |

|

1×120 |

3.1 |

20.3 |

1360 |

|

1×150 |

3.4 |

22.4 |

1660 |

|

1×185 |

3.7 |

24.9 |

2080 |

|

1×240 |

4.0 |

28.1 |

2690 |

|

1×300 |

4.3 |

31.0 |

3330 |