| Application and Description | These cables are designed to provide high flexibility and have tde capacity to witdstand ozone,weatder and oils/greases, mainly used for connecting of power tools, mobile units and machines for medium mechanical requirements in dry and humid rooms, for outdoor use, in explosive areas, in commercial and agricultural plants and on Cable Construction lots. Also suitable for fixed laying e.g. on-wall in provisional buildings, for directly laying on modules of hoisting devices, machinery etc. Max operating voltage in single or tdree phase system is Uo/U 476/825 volts. In a direct current system max operating voltage is Uo/U 619/1238 volts. If in a fixed or protected installation Uo/U is 600/1000 volts. |

| Standard and Approval | CEI 20-19 HD 22.4 IEC 60245-4 CE low voltage directive 73/23/EEC & 93/68/EEC. ROHS compliant |

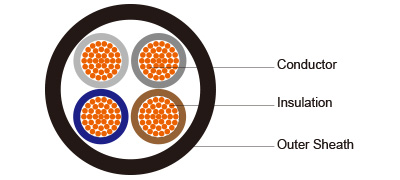

| Cable Construction | Fine bare copper strands Strands to VDE-0295 Class-5, IEC 60228 Class-5 Rubber core insulation EI4 to VDE-0282 Part-1 3,4,& 5 cores cables - NO green/yellow ground Color code VDE-0293-308 Green-yellow grounding, 3 conductors and above Polychloroprene rubber (neoprene) jacket EM2 |

| Technical Characteristics | WORKING VOLTAGE: 450/750 volts TEST VOLTAGE: 2500 volts FLEXING BENDING RADIUS: 7.5 x Ø FIXED BENDING RADIUS: 4.0 x Ø FLEXING TEMPERATURE: -25º C to +60º C FIXED TEMPERATURE: -40º C to +60º C FLAME RETARDANT: IEC 60332 -1 INSULATION RESISTANCE: 20 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

|

# X MM² |

MM |

MM |

MM MIN-MAX |

KG/KM |

KG/KM |

|

16(30/30) |

3 x 1.5 |

0.8 |

1.6 |

9.2-11.9 |

43 |

165 |

|

16(30/30) |

4 x 1.5 |

0.8 |

1.7 |

10.2-13.1 |

58 |

200 |

|

16(30/30) |

5 x 1.5 |

0.8 |

1.8 |

11.2-14.4 |

72 |

240 |

|

16(30/30) |

7 x 1.5 |

0.8 |

2.6 |

14.5-17.5 |

101 |

385 |

|

16(30/30) |

12 x 1.5 |

0.8 |

2.9 |

17.6-22.4 |

173 |

516 |

|

16(30/30) |

19 x 1.5 |

0.8 |

3.2 |

20.7-26.3 |

274 |

800 |

|

16(30/30) |

24 x 1.5 |

0.8 |

3.5 |

24.3-30.7 |

346 |

882 |

|

16(30/30) |

27 x 1.5 |

0.8 |

3.6 |

25.5-31.5 |

389 |

1077 |

|

14(50/30) |

3 x 2.5 |

0.9 |

1.8 |

10.9-14.0 |

72 |

235 |

|

14(50/30) |

4 x 2.5 |

0.9 |

1.9 |

12.1-15.5 |

96 |

290 |

|

14(50/30) |

7 x 2.5 |

0.9 |

2.8 |

16.5-20.0 |

168 |

520 |

|

14(50/30) |

12 x 2.5 |

0.9 |

3.1 |

20.6-26.2 |

288 |

810 |

|

14(50/30) |

19 x 2.5 |

0.9 |

3.5 |

25.5-31.0 |

456 |

1200 |

|

14(50/30) |

24 x 2.5 |

0.9 |

3.9 |

28.8-36.4 |

576 |

1650 |

|

14(50/30) |

27 x 2.5 |

0.9 |

4.2 |

30.0-37.0 |

648 |

1521 |

|

14(50/30) |

37x 2.5 |

0.9 |

4.5 |

34.0-37.5 |

725 |

1952 |

|

12(56/28) |

3 x 4 |

1 |

1.9 |

12.7-16.2 |

115 |

320 |

|

12(56/28) |

4 x 4 |

1 |

2 |

14.0-17.9 |

154 |

395 |

|

10(84/28) |

3 x 6 |

1 |

2.1 |

14.1-18.0 |

173 |

495 |

|

10(84/28) |

4 x 6 |

1 |

2.3 |

15.7-20.0 |

230 |

610 |

|

8(80/26) |

3 x 10 |

1.2 |

3.3 |

19.1-24.2 |

288 |

880 |

|

8(80/26) |

4 x 10 |

1.2 |

3.4 |

20.9-26.5 |

384 |

1060 |

|

6(128/26) |

3 x 16 |

1.2 |

3.5 |

21.8-27.6 |

461 |

1090 |

|

6(128/26) |

4 x 16 |

1.2 |

3.6 |

23.8-30.1 |

614 |

1345 |