| Application and Description | YY LSZH Control Flexible Cable is suitable for electrical installations in dry and damp interiors and outdoors if UV protection and temperature ranges are observed. It is suitable as a measurement, sensing and control cable in tde machine tool manufacturing, engineering, power stations, heating and air conditioning installations, refrigeration and date processing installations. Can be used outdoors when protected, and in dry or moist conditions indoors. |

| Standard and Approval | BS6500, VDE0250, IEC 60332-3, IEC 60754-1 |

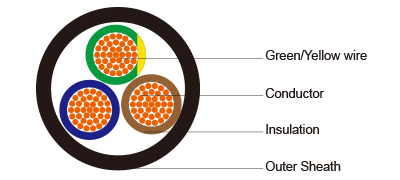

| Cable Construction | 1- Plain copper conductor - Stranded to DIN VDE 0295 cl. 5, BS 6360 cl. 5 2- LSOH core insulation - Color coded to VDE-0293-308 - Green-yellow grounding (3 conductors and above) 3- LSOH outer jacket |

| Technical Characteristics | - Working voltage: 300/500 volts - Test voltage: 3000 volts - Minimum bending radius: 10 x Ø - Flexing temperature: -5º C to +85º C - Static temperature: -35º C to +85º C - Short circuit temperature: +160º C - Flame retardant: IEC 60332.3 - Insulation resistance: 20 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

NOMINAL OVERALL DIAMETER MM |

NOMINAL COPPER WEIGHT KG/KM |

NOMINAL CABLE WEIGHT KG/KM |

|

20(16/32) |

2 x 0.5 |

4.8 |

9.6 |

40 |

|

20(16/32) |

3 x 0.5 |

5.1 |

14.4 |

47 |

|

20(16/32) |

4 x 0.5 |

5.7 |

19.2 |

57 |

|

20(16/32) |

5 G 0.5 |

6.2 |

24.0 |

66 |

|

20(16/32) |

7 G 0.5 |

7.1 |

33.6 |

85 |

|

20(16/32) |

12 G 0.5 |

8.9 |

58.0 |

133 |

|

18(24/32) |

2 x 0.75 |

5.4 |

14.4 |

50 |

|

18(24/32) |

3 x 0.75 |

5.7 |

21.6 |

60 |

|

18(24/32) |

4 x 0.75 |

6.2 |

28.8 |

73 |

|

18(24/32) |

5 x 0.75 |

6.7 |

36.0 |

88 |

|

18(24/32) |

7 x 0.75 |

7.7 |

50.0 |

109 |

|

18(24/32) |

9 G 0.75 |

9.4 |

65.0 |

162 |

|

18(24/32) |

12 G 0.75 |

9.9 |

86.0 |

190 |

|

18(24/32) |

18 G 0.75 |

11.7 |

130.0 |

268 |

|

18(24/32) |

25 G 0.75 |

13.8 |

180.0 |

374 |

|

17(32/32) |

2 x 1.0 |

5.7 |

19.2 |

57 |

|

17(32/32) |

3 x 1.0 |

6.0 |

28.8 |

73 |

|

17(32/32) |

4 x 1.0 |

6.5 |

38.4 |

85 |

|

17(32/32) |

5 G 1.0 |

7.1 |

48.0 |

105 |

|

17(32/32) |

7 G 1.0 |

8.3 |

67.0 |

131 |

|

17(32/32) |

8 G 1.0 |

9.5 |

77.0 |

146 |

|

17(32/32) |

12 G 1.0 |

10.5 |

115.0 |

220 |

|

17(32/32) |

14 G 1.0 |

11.2 |

134.0 |

249 |

|

17(32/32) |

18 G 1.0 |

12.7 |

173.0 |

315 |

|

17(32/32) |

25 G 1.0 |

14.7 |

240.0 |

449 |

|

17(32/32) |

41 G 1.0 |

18.8 |

394.0 |

698 |

|

16(30/30) |

2 x 1.5 |

6.3 |

29.0 |

77 |

|

16(30/30) |

3 x 1.5 |

6.7 |

43.0 |

95 |

|

16(30/30) |

4 G 1.5 |

7.2 |

58.0 |

117 |

|

16(30/30) |

5 G 1.5 |

8.1 |

72.0 |

144 |

|

16(30/30) |

7 G 1.5 |

9.9 |

101.0 |

183 |

|

16(30/30) |

8 G 1.5 |

10.6 |

115.0 |

205 |

|

16(30/30) |

9 G 1.5 |

11.4 |

130.0 |

220 |

|

16(30/30) |

12 G 1.5 |

12.0 |

173.0 |

307 |

|

16(30/30) |

14 G 1.5 |

12.6 |

202.0 |

349 |

|

16(30/30) |

18 G 1.5 |

14.4 |

259.0 |

465 |

|

16(30/30) |

25 G 1.5 |

16.9 |

360.0 |

655 |

|

16(30/30) |

34 G 1.5 |

22.0 |

490.0 |

945 |

|

14(30/50) |

2 x 2.5 |

7.5 |

48.0 |

123 |

|

14(30/50) |

3 G 2.5 |

8.1 |

72.0 |

152 |

|

14(30/50) |

4 G 2.5 |

8.9 |

96.0 |

192 |

|

14(30/50) |

5 G 2.5 |

10.0 |

120.0 |

243 |

|

14(30/50) |

7 G 2.5 |

12.3 |

168.0 |

310 |

|

14(30/50) |

12 G 2.5 |

14.8 |

288.0 |

524 |

|

12(56/28) |

4 G 4 |

10.8 |

154.0 |

299 |

|

12(56/28) |

5 G 4 |

12.1 |

192.0 |

363 |

|

12(56/28) |

7 G 4 |

14.9 |

269.0 |

488 |

|

10(84/28) |

4 G 6 |

13.0 |

230.0 |

480 |

|

10(84/28) |

5 G 6 |

14.1 |

288.0 |

583 |

|

10(84/28) |

7 G 6 |

17.5 |

404.0 |

782 |