| Application and Description | These PVC insulated stranded hook-up wires are employed in telecommunication systems, toys, sports equipment and general wiring equipment used in electrical engineering to meet stringent demands in terms of high and ultra-high flexibility. They are not permitted to be installed in heavy current applications outside of the equipment. |

| Standard and Approval | VDE 0812, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant |

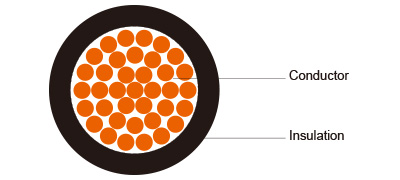

| Cable Construction | - Tinned copper strands - Strands to VDE-0295 Class-5, IEC 60228 Cl-5 and HD383 - Special PVC core insulation, compound YI3 to DIN VDE 0812 - Cores identification to VDE-0293 |

| Technical Characteristics | - Working voltage: 0.14 mm² 500 V/0.25-1.50 mm² 900 V - Test voltage: 0.14 mm² 1200 V/0.25-1.50 mm² 2500 V - Flexing bending radius: 12.5 x Ø - Static bending radius: 12.5 x Ø - Flexing temperature: -5º C to +70º C - Static temperature: -30º C to +80º C(temporary 105 º C for LiYv-t) - Flame retardant: VDE 0472 part 804, test method B, and IEC 60332.1 - Insulation resistance: 10 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

NOMINAL OVERALL DIAMETER MM |

NOMINAL COPPER WEIGHT KG/KM |

NOMINAL CABLE WEIGHT KG/KM |

|

26(18/38) |

1 x 0.14 |

1.1 |

1.4 |

3.0 |

|

24(14/34) |

1 x 0.25 |

1.3 |

2.4 |

4.0 |

|

22(19/34) |

1 x 0.34 |

1.4 |

3.6 |

5.0 |

|

20(16/32) |

1 x 0.50 |

1.8 |

4.8 |

8.0 |

|

18(24/32) |

1 x 0.75 |

2.0 |

7.2 |

10.0 |

|

17(32/32) |

1 x 1.00 |

2.1 |

9.6 |

13.0 |

|

16(30/30) |

1 x 1.50 |

2.6 |

14.4 |

19.0 |

|

14(30/50) |

1 x 2.50 |

3.4 |

24.0 |

31.0 |