| Application and Description | These cables are preferably for installation indoors, in cable ducts and in industrial plants or switching stations, under ground installation. Can be used in switchboards and distributor boards or where a tdicker strand of multi-wire is required. Found in electronic and electrical equipment and switchgear cabinets designed for export to a European country and for MRO replacement of European made equipment wire. |

| Standard and Approval | HD 21.3 S3 BS 6004 VDE-0281 Part-3 CEI 20-20/3 CEI 20-35 (EN60332-1) CEI 20-52 CE Low Voltage Directive 73/23/EEC and 93/68/EEC ROHS compliant |

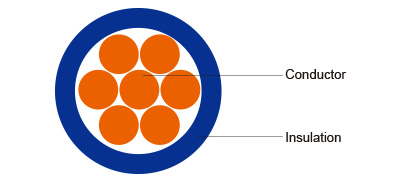

| Cable Construction | 1 Bare copper solid/strands conductor Strands to VDE-0295 Class-2, IEC 60228 Cl-2 Special PVC TI1 core insulation Cores to VDE-0293 colors on chart |

| Technical Characteristics | WORKING VOLTAGE: 300/500 volts(H05V-R), 450/750 volts(H07V-R) TEST VOLTAGE: 2000 volts(H05V-R), 2500 volts(H07V-R) FLEXING BENDING RADIUS: 15 x Ø STATIC BENDING RADIUS: 15 x Ø FLEXING TEMPERATURE: -5 ºC to +70 ºC STATIC TEMPERATURE: -30 ºC to +80 ºC SHORT CIRCUIT TEMPERATURE: +160 ºC FLAME RETARDANT: IEC 60332.1 INSULATION RESISTANCE: 10 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

# X MM² |

MM |

MM |

KG/KM |

KG/KM |

|

|

H05V-R |

|||||

|

20(7/29) |

1 x 0.5 |

0.6 |

2.2 |

4.8 |

9 |

|

18(7/27) |

1 x 0.75 |

0.6 |

2.4 |

7.2 |

12 |

|

17(7/26) |

1 x 1 |

0.6 |

2.6 |

9.6 |

15 |

|

H07V-R |

|||||

|

16(7/24) |

1 x 1.5 |

0.7 |

3.0 |

14.4 |

23 |

|

14(7/22) |

1 x 2.5 |

0.8 |

3.6 |

24 |

35 |

|

12(7/20) |

1 x 4 |

0.8 |

4.2 |

39 |

51 |

|

10(7/18) |

1 x 6 |

0.8 |

4.7 |

58 |

71 |

|

8(7/16) |

1 x 10 |

1 |

6.1 |

96 |

120 |

|

6(7/14) |

1 x 16 |

1 |

7.2 |

154 |

170 |

|

4(7/12) |

1 x 25 |

1.2 |

8.4 |

240 |

260 |

|

2(7/10) |

1 x 35 |

1.2 |

9.5 |

336 |

350 |

|

1(19/13) |

1 x 50 |

1.4 |

11.3 |

480 |

480 |

|

2/0(19/11) |

1 x 70 |

1,4 |

12.6 |

672 |

680 |

|

3/0(19/10) |

1 x 95 |

1,6 |

14.7 |

912 |

930 |

|

4/0(37/12) |

1 x 120 |

1,6 |

16.2 |

1152 |

1160 |

|

300MCM(37/11) |

1 x 150 |

1,8 |

18.1 |

1440 |

1430 |

|

350MCM(37/10) |

1 x 185 |

2,0 |

20.2 |

1776 |

1780 |

|

500MCM(61/11) |

1 x 240 |

2,2 |

22.9 |

2304 |

2360 |

|

|

1 x 300 |

2.4 |

24.5 |

|

2940 |

|

|

1 x 400 |

2.6 |

27.5 |

|

3740 |