| Application and Description | These cables are recommended for tde internal wiring of switchboards and distributor boards as well as 1000V. or direct nominal voltage of 750V. These cables are all allowed for laying in tubes in and under plaster. |

| Standard and Approval | HD 22.7 S2 VDE-0282 Part-7 CEI 20-19/7 CEI 20-35(EN60332-1) CE Low Voltage Directive 73/23/EEC and 93/68/EEC ROHS compliant |

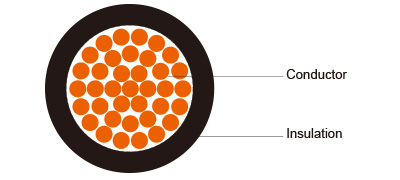

| Cable Construction | 1 Fine bare copper strands Strands to VDE-0295 Class-5, IEC 60228 Class-5 2 Rubber compound type EI3 (EVA) to DIN VDE 0282 part 7 insulation Cores to VDE-0293 colors |

| Technical Characteristics | WORKING VOLTAGE: 300/500v (H05G-K) ; 450/750v (H07G-K) TEST VOLTAGE: 2000volts (H05G-K) ; 2500 volts (H07G-K) FLEXING BENDING RADIUS: 7 x Ø STATIC BENDING RADIUS: 7 x Ø FLEXING TEMPERATURE: -25 ºC to +110 ºC STATIC TEMPERATURE: -40 ºC to +110 ºC FLAME RETARDANT: IEC 60332.1 INSULATION RESISTANCE: 10 MΩ x km |

Cable Parameter

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

# X MM² |

MM |

MM |

KG/KM |

KG/KM |

|

|

H05G-K |

|||||

|

20(16/32) |

1 x 0.5 |

0.6 |

2.3 |

4.8 |

13 |

|

18(24/32) |

1 x 0.75 |

0.6 |

2.6 |

7.2 |

16 |

|

17(32/32) |

1 x 1 |

0.6 |

2.8 |

9.6 |

22 |

|

H07G-K |

|||||

|

16(30/30) |

1 x 1.5 |

0.8 |

3.4 |

14.4 |

24 |

|

14(50/30) |

1 x 2.5 |

0.9 |

4.1 |

24 |

42 |

|

12(56/28) |

1 x 4 |

1.0 |

5.1 |

38 |

61 |

|

10(84/28) |

1 x 6 |

1.0 |

5.5 |

58 |

78 |

|

8(80/26) |

1 x 10 |

1.2 |

6.8 |

96 |

130 |

|

6(128/26) |

1 x 16 |

1.2 |

8.4 |

154 |

212 |

|

4(200/26) |

1 x 25 |

1.4 |

9.9 |

240 |

323 |

|

2(280/26) |

1 x 35 |

1.4 |

11.4 |

336 |

422 |

|

1(400/26) |

1 x 50 |

1.6 |

13.2 |

480 |

527 |

|

2/0(356/24) |

1 x 70 |

1.6 |

15.4 |

672 |

726 |

|

3/0(485/24) |

1 x 95 |

1.8 |

17.2 |

912 |

937 |

|

4/0(614/24) |

1 x 120 |

1.8 |

19.7 |

1152 |

1192 |