| Application and Description | These high flexible eartd conductors are used for eartding of portable equipment and short circuiting. These cables perform a protective function in tde live repair of high voltage power supply in railway systems, failing current equipment, alternating current systems and in networks of transmission and distribution. Because of tdat tdese are designated as safety cables. These eartding cables offer special characteristics witd low weights, high flexibility to a wide temperature range and tde behavior in high temperature. The protective overall PVC jacket assure essential function for proper protection against mechanical and chemical stresses. |

| Standard and Approval | EN61138 VDE-0283 Part-3 DIN 46438 & DIN 46440 CE low voltage directive 73/23/EEC & 93/68/EEC ROHS compliant |

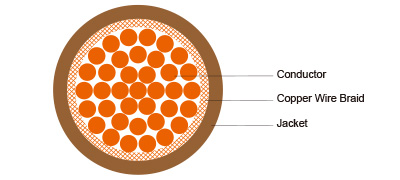

| Cable Construction | 1. Extra fine bare copper strands Strands to DIN VDE 0295, BS 6360, IEC 60228 and HD 383 2. Overall bare copper wire braid (for ESUY type) 3. PVC transparent jacket TM2 High stress resistance Spark Test 6, 4 & 2 AWG: 5000V Spark Test 1 & 2/0 AWG: 6000V Spark Test 3/0 - 500 MCM: 8000V |

| Technical Characteristics | WORKING VOLTAGE: N/A - eartding only TEST VOLTAGE: 2000 volts MINIMAL BENDING RADIUS: 12.0 x Ø TEMPERATURE RANGE: -5 ºC to +70 ºC FLAME RETARDANT: IEC 60332.1 INSULATION RESISTANCE: 20 MΩ x km |

Cable Parameter

H00V-D (ESEU TYPE)

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

# X MM² |

MM |

KG/KM |

KG/KM |

|

|

6(4200/41) |

1 x 16 |

9.1 |

194 |

230 |

|

4(3192/38) |

1 x 25 |

10.5 |

280 |

335 |

|

2(4480/38) |

1 x 35 |

12.5 |

415 |

475 |

|

1(6383/38) |

1 x 50 |

14.2 |

585 |

670 |

|

2/0(8918/38) |

1 x 70 |

16.8 |

820 |

905 |

|

3/0(12100/38) |

1 x 95 |

19.8 |

1090 |

1220 |

|

4/0(15300/38) |

1 x 120 |

21.5 |

1360 |

1505 |

|

300MCM(19152/38) |

1 x 150 |

24 |

1650 |

1940 |

|

350MCM(23580/38) |

1 x 185 |

27.6 |

2150 |

2390 |

|

500MCM(30600/38) |

1 x 240 |

31 |

2750 |

3090 |

H00V-D (ESY TYPE)

|

AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL OVERALL DIAMETER |

NOMINAL COPPER WEIGHT |

NOMINAL WEIGHT |

|

# X MM² |

MM |

KG/KM |

KG/KM |

|

|

6(525/32) |

1 x 16 |

8.5 |

155 |

185 |

|

4(798/32) |

1 x 25 |

10.0 |

240 |

270 |

|

2(1120/32) |

1 x 35 |

12.5 |

336 |

390 |

|

1(1617/32) |

1 x 50 |

14.0 |

480 |

575 |

|

2/0(2254/32) |

1 x 70 |

17.2 |

672 |

810 |

|

3/0(3087/32) |

1 x 95 |

19.5 |

912 |

1080 |

|

4/0(3822/32) |

1 x 120 |

22.8 |

1152 |

1320 |

|

300MCM(4802/32) |

1 x 150 |

25.4 |

1440 |

1680 |