0.6/1kV 4 Cores Copper Tape Screened GSWA CU/XLPE/LSZH/CT/LSZH/SWA/LSZH Power Cable

CU/XLPE/LSZH/CT/LSZH/SWA/LSZH (4 Cores)

XLPE Insulated, LSZH Bedded, Copper Tape Screened, LSZH Sheathed, Galvanised Steel Wire

Armoured, LSZH Sheathed Cable

Application

These power cable for fixed installations such as distribution networks or industrial installations.

Such as Plant engineering; Industrial machinery; Heating and air-conditioning systems; Power stations; Stage applications etc.

Armoured cable suitable for direct burial.

Construction

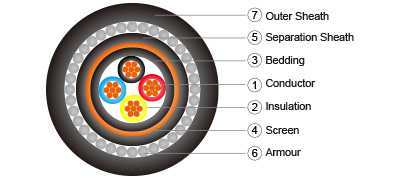

Conductor: Plain annealed copper, class1 solid or class 2 stranded acc. to IEC 60228.

Flexible class 5 or tinned conductor could be offer upon request.

Insulation: Cross-linked polyethlene (XLPE) compound as per IEC 60502-1.

Insulation Color Code:

| Number of Cores | Color Code to IEC 60502-1 | Color Code to BS 5467 |

| 4 | Red, Yellow, Blue, Green/ Yellow or Others |

Brown, Black, Grey, Green/ Yellow |

Assembly: Cores cabled together with PP filler and covered with non-woven tape.

Bedding: Low smoke zero halogen (LSZH) compound type ST8 (90°C) of IEC 60502-1.

Bedding Color: Black.

Screen: Copper tape.

Separation Sheath: Low smoke zero halogen (LSZH) compound type ST8 (90°C) of IEC 60502-1.

Separation Sheath Color: Black.

Armour: Galvanized Steel wire armoured (SWA).

Outer Sheath: Low smoke zero halogen (LSZH) compound type ST8 (90°C) of IEC 60502-1.

Outer Sheath Color: Black or other color as per customer request.

Electrical Characteristics

Recommended rated voltages U0

| Highest system voltage (Um) (kV) |

Rated voltage (U0) (kV) | |

| Categories A and B | Category C | |

| 1,2 | 0,6 | 0,6 |

Routine test voltages

| Rated voltage U0 (kV) | 0,6 |

| Test voltage (kV) | 3,5 |

Maximum conductor temperatures for different types of insulating compound

| Maximum conductor temperature (°C) | |

| Normal operation | Short-circuit (5 s maximum duration) |

| 90 | 250 |

Operating Temperature: -15°C to 90°C

Test Voltage: 3.5 kV for 5 minutes

Installation Reference

Min.Bending Radius (mm): 8 x cable overall diameter

Max.Pulling Tension (N/mm2): 70

Reference Standards

Design Specification: IEC60502-1

Conductor: IEC60228, BS EN60228

Flame Retardancy: IEC60332-3-22, BS EN60332-3-22

Low Smoke Zero Halogen: IEC61034-2, BS EN61034-2, IEC60754-1, IEC60754-2, BS EN50267-2-1, BS EN50267-2-2

Dimension

| Nominal Conductor Area(mm2) | No.and Diameter of Wires (no./mm) |

Thickness of Insulation (mm) |

Diameter Under Screen (mm) |

Diameter Under Armour (mm) |

Armour Wire Diameter (mm) |

Overall Diameter (mm) |

Approxi mate Weight (kg/km) |

| 4X1.5 | 7/0.53 | 0.7 | 9.7 | 13.1 | 1.25 | 19.9 | 871 |

| 4X2.5 | 7/0.67 | 0.7 | 10.7 | 14.1 | 1.25 | 20.9 | 981 |

| 4X4 | 7/0.85 | 0.7 | 12 | 15.4 | 1.25 | 22.2 | 1127 |

| 4X6 | 7/1.04 | 0.7 | 13.4 | 16.8 | 1.25 | 23.6 | 1304 |

| 4X10 | 7/1.35 | 0.7 | 15.6 | 19 | 1.6 | 26.5 | 1758 |

| 4X16 | 7/1.70 | 0.7 | 18.2 | 21.6 | 1.6 | 29.1 | 2186 |

| 4X25 | 7/2.14 | 0.9 | 22.3 | 25.7 | 1.6 | 33.4 | 2915 |

| 4X35 | 7/2.52 | 0.9 | 25.1 | 28.5 | 1.6 | 36.4 | 3535 |

| 4X50 | 19/1.78 | 1 | 25.4 | 28.8 | 2 | 37.7 | 4370 |

| 4x70 | 19/2.14 | 1.1 | 29.8 | 33.2 | 2 | 42.5 | 5651 |

| 4x95 | 19/2.52 | 1.1 | 33.5 | 37.1 | 2.5 | 47.6 | 7413 |

| 4x120 | 37/2.03 | 1.2 | 37.3 | 41.1 | 2.5 | 52 | 8888 |

| 4x150 | 37/2.25 | 1.4 | 42.8 | 46.8 | 2.5 | 58.1 | 10632 |

| 4x185 | 37/2.52 | 1.6 | 47.4 | 51.4 | 2.5 | 62.9 | 12641 |

| 4x240 | 61/2.25 | 1.7 | 54.7 | 59.3 | 2.5 | 71.2 | 16133 |

| 4x300 | 61/2.52 | 1.8 | 60.6 | 65.4 | 3.15 | 79.2 | 20227 |