VDE Ref Code

| PVC Sheath Version | RE-2Y(St)Y (Overall Screen) RE-2Y(St)Y PiMF(Individual Screen+Overall Screen) RE-2Y(St)Y-SWA(Overall Screen+Steel Wire Armour) RE-2Y(St)Y PiMF-SWA(Individual Screen+Overall Screen+Steel Wire Armour) |

| LSOH Sheath Version: | RE-2Y(St)H (Overall Screen) RE-2Y(St)HPiMF(Individual Screen+Overall Screen) RE-2Y(St)-SWA(Overall Screen+Steel Wire Armour) RE-2Y(St)HPiMF-SWA(Individual Screen+Overall Screen+ Steel Wire Armour |

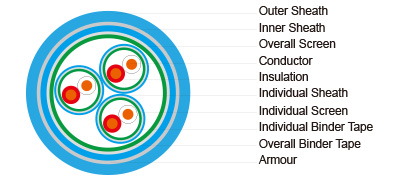

Construction

| Construction: | Annealed solid copper(Class 1),stranded(Class2), or fiexible(Class 5) to BS5360 . |

| Binder tape: | A 23 micron p.e.t.p.tape applied with a minimum 50% overlap. |

| Insulation: | Polyethylene to BS 6234 Type 03. |

| Collective screen: | Aluminium/p.e.t.p.laminated tape applied with the metallic side down in electrical contact with a 0.5mm 2 tinned copper drain wire over the p.e.t.p.binder tape. |

| Pair identification: | a)Collectively screened cables:Colour coded in accordance with Colour Code Chart 1 on page3 b)Individually screened pairs:One blue core and one black core in each pair.Pairs identified by numbered screen isolation tape. |

| Outer protection: | Type 1 Extruded flame retardant PVC sheath. Type 2 Extruded polyethylene bedding,alvanised steel wire armour,extruded flame retardant PVC sheath. |

| Pair screens: | Aluminium/p.e.t.p.Laminated tape applied with the metallic side down in electrical contact with a 0.5 mm 2 tinned copper drain wire. A 23 micron isolation tape is applied over the screening tape with a minimum 50% overlap. |

| Minimum bending radius: | Type 1: 8 x diameter. Type 2: 12xdiameter. |

| Voltage rating: | 300 volt core to earth and 500 volt core to core at maximum temperature of 65℃ |

| Temperature rating: | During Operation:-40℃+70℃ During Operation:-0℃+50℃ |

These cables are not for direct connection to the public mains supply

Electrical characteristics

|

Parameter |

Note |

Unit |

Conductor size |

|||||

|

0.5mm² (1/0.8mm) |

0.5mm² (16/0.2mm) |

0.75mm² (24/0.2mm) |

1.0mm² (1/1.13mm) |

1.5mm² (7/0.53mm) |

||||

|

Conductor resistance |

max. |

Ω/Km |

36.8 |

39.7 |

26.5 |

18.2 |

12.3 |

|

|

Insulation resistance |

max. |

GΩxKm |

5 |

5 |

5 |

5 |

5 |

|

|

Mutual capacitance at 1 kH -One pair and two pair(Quad)cables with collective screen and all cables with individually screened pairs -Cables with only collective screen except one pair and two pair(Quad) |

max. |

pF/m |

115 |

115 |

115 |

115 |

115 |

|

|

75 |

75 |

75 |

75 |

75 |

||||

|

Capacitance unbalance at 1 kHz |

max. |

pF/250m |

250 |

250 |

250 |

250 |

250 |

|

|

Inductance/resistance ratio(L/R) |

max. |

μH/Ω |

25 |

25 |

25 |

25 |

25 |

|

|

Test voltage |

(Core:core) |

- |

V |

1000 |

1000 |

1000 |

1000 |

1000 |

|

(Core:core) |

V |

1000 |

1000 |

1000 |

1000 |

1000 |

||

|

Rated voltage |

max. |

V |

300/500 |

300/500 |

300/500 |

300/500 |

300/500 |

|

MULTIPAIR INSTRUMENTATION CABLES(UNARMOURED)

TO BS 5308 PART 1-COLLECTIVELY SCREENED

|

Conductor |

Number of Pairs |

Nominal Overall Dia(mm) |

Approx Weight (kg/km) |

|

1/0.8mm (0.5mm² ) |

1 |

5.7 |

40 |

|

2(Quad) |

6.5 |

60 |

|

|

5 |

11.0 |

130 |

|

|

10 |

14.4 |

220 |

|

|

20 |

18.8 |

380 |

|

|

30 |

22.4 |

540 |

|

|

16/0.2mm (0.5mm² ) |

1 |

6.4 |

60 |

|

2(Quad) |

7.3 |

80 |

|

|

5 |

12.5 |

200 |

|

|

10 |

16.6 |

340 |

|

|

20 |

21.7 |

570 |

|

|

30 |

26.3 |

790 |

|

|

24/0.2mm (0.75mm² ) |

1 |

6.7 |

75 |

|

2(Quad) |

7.7 |

100 |

|

|

5 |

13.7 |

250 |

|

|

10 |

18.1 |

450 |

|

|

20 |

23.9 |

800 |

|

|

30 |

28.9 |

1130 |

|

|

1/1.13mm (1.0mm²) |

1 |

6.8 |

85 |

|

2(Quad) |

7.8 |

115 |

|

|

5 |

13.7 |

290 |

|

|

10 |

17.8 |

500 |

|

|

20 |

23.8 |

950 |

|

|

30 |

28.4 |

1330 |

|

|

7/0.53mm (1.5mm² ) |

1 |

7.7 |

100 |

|

2(Quad) |

9.1 |

150 |

|

|

5 |

15.8 |

360 |

|

|

10 |

21.0 |

670 |

|

|

20 |

27.9 |

1230 |

|

|

30 |

33.7 |

1720 |

MULTIPAIR INSTRUMENTATION CABLES(UNARMOURED)

TO BS 5308 PART 1 TYPE 1-INDIVIDUAL PAIR AND COLLECTIVELY SCREENED

|

Conductor |

Number of Pairs |

Nominal Overall Dia(mm) |

Approx Weight (kg/km) |

|

1/0.8mm (0.5mm² ) |

2 |

9.7 |

100 |

|

5 |

12.9 |

190 |

|

|

10 |

17.7 |

320 |

|

|

20 |

22.9 |

570 |

|

|

30 |

27.3 |

820 |

|

|

16/0.2mm (0.5mm² ) |

2 |

11.4 |

160 |

|

5 |

14.6 |

250 |

|

|

10 |

20.5 |

480 |

|

|

20 |

26.7 |

780 |

|

|

30 |

31.7 |

1100 |

|

|

24/0.2mm (0.75mm² ) |

2 |

12.2 |

190 |

|

5 |

15.7 |

270 |

|

|

10 |

21.8 |

550 |

|

|

20 |

28.5 |

960 |

|

|

30 |

33.7 |

1320 |

|

|

1/1.13mm (1.0mm² ) |

2 |

12.2 |

190 |

|

5 |

15.6 |

270 |

|

|

10 |

22.0 |

480 |

|

|

20 |

29.2 |

910 |

|

|

30 |

34.8 |

1320 |

|

|

7/0.53mm (1.5mm² ) |

2 |

13.7 |

250 |

|

5 |

17.8 |

400 |

|

|

10 |

25.2 |

800 |

|

|

20 |

33.8 |

1400 |

|

|

30 |

40.0 |

2040 |

MULTIPAIR INSTRUMENTATION CABLES (ARMOURED)

TO BS 5308 PART 1 TYPE 2-COLLECTIVELY SCREENED

|

Conductor |

Number of Pairs |

Nominal Dia under Armour (mm) |

Nominal Overall Dia(mm) |

Armour Wire Dia(mm) |

Approx Weight (kg/km) |

|

1/0.8mm (0.5mm² ) |

1 |

5.3 |

10.1 |

0.9 |

225 |

|

2(Quad) |

6.1 |

10.9 |

0.9 |

250 |

|

|

5 |

10.6 |

15.6 |

0.9 |

430 |

|

|

10 |

14.0 |

20.1 |

1.25 |

730 |

|

|

20 |

18.4 |

25.4 |

1.6 |

1200 |

|

|

30 |

22.0 |

29.2 |

1.6 |

1500 |

|

|

16/0.2mm (0.5mm²) |

1 |

4.5 |

10.8 |

0.9 |

250 |

|

2(Quad) |

6.9 |

11.7 |

0.9 |

300 |

|

|

5 |

9.9 |

17.3 |

0.9 |

560 |

|

|

10 |

16.2 |

22.3 |

1.25 |

970 |

|

|

20 |

22.3 |

28.5 |

1.6 |

1640 |

|

|

30 |

32.9 |

33.3 |

1.6 |

2110 |

|

|

24/0.2mm (0.75mm² ) |

1 |

6.3 |

11.1 |

0.9 |

280 |

|

2(Quad) |

7.3 |

12.3 |

0.9 |

330 |

|

|

5 |

13.3 |

19.2 |

1.25 |

750 |

|

|

10 |

17.7 |

24.7 |

1.6 |

1260 |

|

|

20 |

23.5 |

30.7 |

1.6 |

1890 |

|

|

30 |

28.5 |

36.9 |

1.6 |

2440 |

|

|

1/1.13mm (1.0mm² ) |

1 |

6.4 |

11.2 |

0.9 |

290 |

|

2(Quad) |

7.4 |

12.4 |

0.9 |

345 |

|

|

5 |

13.2 |

19.1 |

1.25 |

790 |

|

|

10 |

17.4 |

23.7 |

1.25 |

1310 |

|

|

20 |

23.3 |

30.6 |

1.6 |

2040 |

|

|

30 |

28.0 |

35.6 |

1.6 |

2640 |

|

|

7/0.53mm (1.5mm²) |

1 |

7.3 |

12.3 |

0.9 |

330 |

|

2(Quad) |

13.3 |

13.7 |

0.9 |

420 |

|

|

5 |

21.1 |

21.5 |

1.25 |

940 |

|

|

10 |

27.4 |

27.8 |

1.25 |

1050 |

|

|

20 |

27.5 |

35.1 |

1.6 |

2400 |

|

|

30 |

27.8 |

41.9 |

1.6 |

3120 |

MULTIPAIR INSTRUMENTATION CABLES(ARMOURED)

TO BS 5308 PART1TYPE 2-INDIVIDUAL PAIR AND COLLECTIVELY SCREENED

|

Conductor |

Number of Pairs |

Nominal Dia under Armour (mm) |

Nominal Overall Dia(mm) |

Armour Wire Dia(mm) |

Approx Weight (kg/km) |

|

1/0.8mm (0.5mm² ) |

2 |

10.1 |

14.3 |

0.9 |

411 |

|

5 |

13.5 |

18.4 |

1.25 |

686 |

|

|

10 |

18.3 |

23.6 |

1.25 |

1037 |

|

|

20 |

23.5 |

29.7 |

1.6 |

1664 |

|

|

30 |

27.9 |

34.3 |

1.6 |

2136 |

|

|

16/0.2mm (0.5mm² ) |

2 |

12.0 |

15.8 |

0.9 |

460 |

|

5 |

15.2 |

20.1 |

1.25 |

760 |

|

|

10 |

21.1 |

27.0 |

1.6 |

1300 |

|

|

20 |

27.3 |

33.3 |

1.6 |

1870 |

|

|

30 |

32.3 |

39.6 |

2.0 |

2620 |

|

|

24/0.2mm (0.75mm² ) |

2 |

12.8 |

16.8 |

0.9 |

500 |

|

5 |

16.2 |

21.1 |

1.25 |

920 |

|

|

10 |

22.6 |

28.6 |

1.6 |

1610 |

|

|

20 |

29.8 |

37.0 |

2.0 |

2420 |

|

|

1/1.13mm (1.0mm²) |

2 |

12.8 |

17.0 |

0.9 |

515 |

|

5 |

16.2 |

21.3 |

1.25 |

950 |

|

|

10 |

22.6 |

28.8 |

1.6 |

1670 |

|

|

20 |

29.8 |

37.2 |

2.0 |

2540 |

|

|

7/0.53mm (1.5mm² ) |

2 |

14.7 |

19.5 |

1.25 |

730 |

|

5 |

18.4 |

24.5 |

1.6 |

1180 |

|

|

10 |

26.5 |

32.3 |

1.6 |

1820 |

|

|

20 |

28.0 |

41.3 |

2.0 |

3030 |

COLOUR CODE CHART 1

(For Multipair PE insulated Collective Screened Cables to BS 5308 Part1.)

Two-pair unscreened cables are cabled in quad formation and colour coded in clockwise order of rotation,

black,blue,green,brown.

All other cables up to 50 pairs conform to the following coding:

|

Pair No. |

‘A' Wire |

‘B' Wire |

Pair No. |

‘A' Wire |

‘B' Wire |

|

1 |

Black |

Blue |

26 |

White |

Yellow |

|

2 |

Black |

Green |

27 |

Red |

Yellow |

|

3 |

Blue |

Green |

28 |

Orange |

Yellow |

|

4 |

Black |

Brown |

29 |

Black |

Grey |

|

5 |

Blue |

Brown |

30 |

Blue |

Grey |

|

6 |

Green |

Brown |

31 |

Green |

Grey |

|

7 |

Black |

White |

32 |

Brown |

Grey |

|

8 |

Blue |

White |

33 |

White |

Grey |

|

9 |

Green |

White |

34 |

Red |

Grey |

|

10 |

Brown |

White |

35 |

Orange |

Grey |

|

11 |

Black |

Red |

36 |

Yellow |

Grey |

|

12 |

Blue |

Red |

37 |

Black |

Violet |

|

13 |

Green |

Red |

38 |

Blue |

Violet |

|

14 |

Brown |

Red |

39 |

Green |

Violet |

|

15 |

White |

Red |

40 |

Brown |

Violet |

|

16 |

Black |

Orange |

41 |

White |

Violet |

|

17 |

Blue |

Orange |

42 |

Red |

Violet |

|

18 |

Green |

Orange |

43 |

Orange |

Violet |

|

19 |

Brown |

Orange |

44 |

Yellow |

Violet |

|

20 |

White |

Orange |

45 |

Grey |

Violet |

|

21 |

Red |

Orange |

46 |

Black |

Turquoise |

|

22 |

Black |

Yellow |

47 |

Blue |

Turquoise |

|

23 |

Blue |

Yellow |

48 |

Green |

Turquoise |

|

24 |

Green |

Yellow |

49 |

Brown |

Turquoise |

|

25 |

Brown |

Yellow |

50 |

White |

Turquoise |

ORDERING OPTIONS:

1) Conductor:Bare or Tinned Conductor

2)Conductor Size:Solid or Stranded(to IEC 228 Class 2 or 5 or 6)

|

Size |

Class1 |

Class2 |

Class5 |

Class6 |

|

0.5mm ² |

1/0.8mm |

7/0.3mm |

16/0.2mm |

28/0.15mm |

|

0.75mm ² |

7/0.43mm |

24/0.2mm |

42/0.15mm |

|

|

1.0mm ² |

1/1.13mm |

7/0.44mm |

32/0.2mm |

56/0.15mm |

|

1.5mm ² |

7/0.53mm |

30/0.25mm |

84/0.15mm |

|

|

2.5mm ² |

7/0.67mm |

50/0.25mm |

140/0.15mm |

3)Insulation:PE/XLPE/LSF/LSOH

4)Screening:Aluminium Tape/Copper Braiding

5)Cabling:Multicore/Multipair/Multitriple

6)Bedding&Sheathing Material:PE/PVC/LSF/LSOH

7)Armouring:Steel Tape Armouring/Steel Wire Armouring

8)Fire Performance:

IEC 332-1(For Flame Retardant PVC sheath)

IEC 332-3C(For Flame Retardant PVC or LSOH sheath)

IEC 1034 Part 1&2 (For LSOH sheath)

IEC 754 Part 1&2 (5%-15% for LSF sheath & 0.5% for LSOH sheath)

Oxygen Index(32%-40% depending on different LSOH compound )

Temperature Index(250 ℃ to 300 ℃,depending on different LSOH compound)

2.BS5308 Part 2

BS5308 Part2 Instrumentation Cable PVC Insulated

|

VDE Ref Code |

|

|

PVC Sheath Version |

RE-Y(St)Y (Overall Screen) |

|

LSOH Sheath Version: |

RE-H (St)H(Overall Screen) |

|

Construction |

|

|

Conductor |

Annealed solid copper(Class 1),stranded(Class2), or fiexible(Class 5) to BS5360. |

|

Core/Pair identification |

Multicore cables:Up to 40 cores-yellow cores with black numbers 41-80 cores-black cores with black numbers |

|

Pair screens |

Aluminium/p.e.t.p.Laminated tape applied with the metallic side down in electrical contact with a 0.5 mm 2 tinned copper drain wire. |

|

Voltage rating |

300 volt core to earth and 500 volt core to core at maximum temperature of 65 ℃ |

|

Binder tape |

A 23 micron p.e.t.p.tape applied with the metallic side down in electrica contact with a 0.5 0.5mm 2 tinned copper drain wire over the p.e.t.p.binder tape. |

|

Collective screen |

Aluminium/p.e.t.p.laminated tape applied with the metallic side down in electrical contact with a 0.5mm 2 tinned copper drain wire over the p.e.t.p.binder tape. |

|

Outer protection |

Type 1 Extruded flame retardant PVC sheath. |

|

Minimum bending radius |

Type 1 8 x diameter. |

|

Temperature rating |

During Operation:-40 ℃+70℃ |

These cables are not for direct connection to the public mains supply

Electrical characteristics

|

Parameter |

Note |

Unit |

Conductor size |

|||

|

0.5mmsq (16/0.2mm) |

0.75mmsq (24/0.2mm) |

1.5mmsq (7/0.53mm) |

||||

|

Conductor resistance |

Multicore |

max. |

Ω/Km |

39 |

26 |

12.1 |

|

Multipair |

39.7 |

26.5 |

12.3 |

|||

|

Insulation resistance |

max. |

GΩxKm |

25 |

25 |

25 |

|

|

Mutual capacitance at 1 kH Mutual capacitance of the pairs or adjacent cores |

max. |

pF/m |

250 |

250 |

250 |

|

|

Capacitance between any core or screen |

max. |

pF/250m |

450 |

450 |

450 |

|

|

Inductance/resistance ratio(L/R) |

max. |

μH/Ω |

25 |

25 |

40 |

|

|

Test voltage |

(Core:core) |

- |

V |

1000 |

1000 |

1000 |

|

(Core:core) |

V |

1000 |

1000 |

1000 |

||

|

Rated voltage |

max. |

V |

300/500 |

300/500 |

300/500 |

|

MULTICORE INSTRUMENTATION CABLES (UNARMOURED)

TO BS 5308 PART 2-COLLECTIVELY SCREENED

|

Part No. |

Conductor |

Number of Pairs |

Nominal Overall Dia(mm) |

Approx Weight (kg/km) |

|

BS5308-PVC-MC-CS-16*0.2mm |

16/0.2mm (0.5mm² ) |

2 |

6.4 |

60 |

|

3 |

6.7 |

72 |

||

|

4 |

7.3 |

80 |

||

|

6 |

8.7 |

110 |

||

|

10 |

11.3 |

176 |

||

|

20 |

14.3 |

310 |

||

|

40 |

19.5 |

568 |

||

|

BS5308-PVC-MC-CS-24*0.2mm |

24/0.2mm (0.5mm² ) |

2 |

6.7 |

75 |

|

3 |

7.1 |

90 |

||

|

4 |

7.7 |

100 |

||

|

6 |

9.3 |

138 |

||

|

10 |

12.1 |

220 |

||

|

20 |

15.4 |

388 |

||

|

40 |

21.1 |

710 |

||

|

BS5308-PVC-MC-CS-7*0.53mm |

7/0.53mm (1.0mm² ) |

2 |

7.7 |

103 |

|

3 |

8.3 |

135 |

||

|

4 |

9.1 |

150 |

||

|

6 |

11.1 |

205 |

||

|

10 |

14.1 |

330 |

||

|

20 |

18.1 |

580 |

||

|

40 |

24.0 |

1065 |

MULTIPAIR INSTRUMENTATION CABLES (UNARMOURED) TO BS 5308

PART 2 TYPE 1- COLLECTIVELY SCREENED

|

Conductor |

Number of Pairs |

Nominal Overall Dia(mm) |

Approx Weight (kg/km) |

|

16/0.2mm (0.5mm² ) |

1 |

6.4 |

60 |

|

2(Quad) |

7.3 |

80 |

|

|

5 |

12.5 |

200 |

|

|

10 |

16.6 |

340 |

|

|

20 |

21.7 |

570 |

|

|

30 |

26.3 |

790 |

|

|

24/0.2mm (0.75mm² ) |

1 |

6.7 |

75 |

|

2(Quad) |

7.7 |

100 |

|

|

5 |

13.7 |

250 |

|

|

10 |

18.1 |

450 |

|

|

20 |

23.9 |

800 |

|

|

30 |

28.9 |

1130 |

|

|

7/0.53mm (1.5mm² ) |

1 |

7.7 |

100 |

|

2(Quad) |

9.1 |

150 |

|

|

5 |

15.8 |

360 |

|

|

10 |

21.0 |

670 |

|

|

20 |

27.9 |

1230 |

|

|

30 |

33.7 |

1720 |

MULTICORE INSTRUMENTATION CABLES(ARMOURED)

TO BS 5308 PART 2 TYPE 2-COLLECTIVELY SCREENED

|

Conductor |

Number of Pairs |

Nominal Dia under Armour (mm) |

Nominal Overall Dia (mm) |

Armour Wire Dia(mm) |

Approx Weight (kg/km) |

|

16/0.2mm (0.5mm²) |

2 |

6.0 |

10.8 |

0.9 |

255 |

|

3 |

6.3 |

11.1 |

0.9 |

280 |

|

|

4 |

6.9 |

11.7 |

0.9 |

305 |

|

|

6 |

8.3 |

13.3 |

0.9 |

360 |

|

|

10 |

10.9 |

16.1 |

0.9 |

510 |

|

|

20 |

13.9 |

20.0 |

1.25 |

860 |

|

|

40 |

19.1 |

26.1 |

1.6 |

1440 |

|

|

24/0.2mm (0.75mm²) |

2 |

6.3 |

11.1 |

0.9 |

280 |

|

3 |

6.7 |

11.5 |

0.9 |

305 |

|

|

4 |

7.3 |

12.3 |

0.9 |

335 |

|

|

6 |

8.9 |

13.9 |

0.9 |

400 |

|

|

10 |

11.7 |

16.9 |

0.9 |

565 |

|

|

20 |

15.0 |

21.1 |

1.25 |

950 |

|

|

40 |

20.7 |

27.9 |

1.6 |

1590 |

|

|

7/0.53mm (1.5mm²) |

2 |

7.3 |

12.3 |

0.9 |

330 |

|

3 |

7.9 |

12.9 |

0.9 |

380 |

|

|

4 |

8.7 |

13.7 |

0.9 |

420 |

|

|

6 |

10.7 |

15.7 |

0.9 |

540 |

|

|

10 |

13.7 |

19.8 |

0.9 |

750 |

|

|

20 |

17.7 |

24.7 |

1.25 |

1260 |

|

|

40 |

23.6 |

31.0 |

1.6 |

2140 |

MULTIPAIR INSTRUMENTATION CABLES(ARMOURED)TO

BS 5308 PART2TYPE 2- COLLECTIVELY SCREENED

|

Conductor |

Number of Pairs |

Nominal Dia under Armour (mm) |

Nominal Overall Dia (mm) |

Armour Wire Dia(mm) |

Approx Weight (kg/km) |

|

16/0.2mm (0.5mm²) |

1 |

6.0 |

6.0 |

10.8 |

255 |

|

2(Quad) |

7.85 |

7.85 |

11.7 |

305 |

|

|

5 |

12.1 |

12.1 |

17.3 |

610 |

|

|

10 |

16.2 |

16.2 |

22.3 |

1060 |

|

|

20 |

22.6 |

22.6 |

28.5 |

1800 |

|

|

30 |

26.4 |

26.4 |

33.3 |

2320 |

|

|

24/0.2mm (0.75mm²) |

1 |

6.5 |

6.5 |

11.1 |

305 |

|

2(Quad) |

7.4 |

7.4 |

12.3 |

360 |

|

|

5 |

17.3 |

17.3 |

19.2 |

820 |

|

|

10 |

17.7 |

17.7 |

24.7 |

1380 |

|

|

20 |

23.0 |

23.0 |

30.7 |

2080 |

|

|

30 |

29.7 |

29.7 |

36.9 |

2660 |

|

|

7/0.53mm (1.5mm²) |

1 |

7.5 |

12.3 |

0.9 |

360 |

|

2(Quad) |

8.7 |

13.7 |

0.9 |

460 |

|

|

5 |

16.7 |

21.5 |

1.25 |

1040 |

|

|

10 |

21.1 |

27.8 |

1.6 |

1160 |

|

|

20 |

28.0 |

35.1 |

2.0 |

2630 |

ORDERING OPTIONS:

1) Conductor:Bare or Tinned Conductor

2)Conductor Size:Solid or Stranded(to IEC 228 Class 2 or 5 or 6)

|

Size |

Class1 |

Class2 |

Class5 |

Class6 |

|

0.5mm² |

1/0.8mm |

7/0.3mm |

16/0.2mm |

28/0.15mm |

|

0.75mm² |

7/0.43mm |

24/0.2mm |

42/0.15mm |

|

|

1.0mm² |

1/1.13mm |

7/0.44mm |

32/0.2mm |

56/0.15mm |

|

1.5mm² |

7/0.53mm |

30/0.25mm |

84/0.15mm |

|

|

2.5mm² |

7/0.67mm |

50/0.25mm |

140/0.15mm |

3)Insulation:PE/XLPE/LSF/LSOH

4)Screening:Aluminium Tape/Copper Braiding

5)Cabling:Multicore/Multipair/Multitriple

6)Bedding&Sheathing Material:PVC/LSF/LSOH

7)Armouring:Steel Tape Armouring/Steel Wire Armouring

8)Fire Performance:

IEC 332-1(For Flame Retardant PVC sheath)

IEC 332-3C(For Flame Retardant PVC or LSOH sheath)

IEC 1034 Part 1&2 (For LSOH sheath)

IEC 754 Part 1&2 (5%-15% for LSF sheath & 0.5% for LSOH sheath)

Oxygen Index(32%-40% depending on different LSOH compound )

Temperature Index(250 ℃ to 300 ℃,depending on different LSOH compound)