| Applications | These cables are designed for use in heavy duty services as power supply cable, mobile and portable electrical. |

| Standards | ICEA S-75-381/NEMA WC 58 ASTM B 172 ASTM B 33 CAN/CSA C22.2 No. 96 |

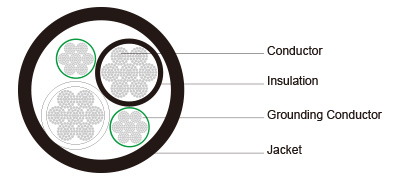

| Construction | |

| Conductors | Stranded annealed tinned copper conductor. |

| Insulation | Ethylene Propylene Rubber (EPR). |

| Grounding Conductor | Tinned copper conductor with a green outer covering. |

| Jacket | Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.) |

| Options | Other jacket materials such as CSP/PCP/NBR/PVC are available upon request. Two-layer jacket with reinforcing fibre between the two layers can be offered as an option. |

| Mechanical and Thermal Properties | Minimum Bending Radius: 6×OD Maximum Operating Temperature: +90℃ |

Dimensions and Weight:

|

Construction |

No. of Strands |

Grounding Conductor Size |

Nominal Insulation Thickness |

Nominal Jacket Thickness |

Nominal Overall Diameter |

Nominal Weight |

Ampacity |

||||

|

No. of cores×AWG/kcmil |

- |

AWG/kcmil |

inch |

mm |

inch |

mm |

inch |

mm |

lbs/kft |

kg/km |

A |

|

2×8 |

133 |

10 |

0.06 |

1.5 |

0.110 |

2.8 |

0.81 |

20.6 |

495 |

736 |

72 |

|

2×6 |

259 |

10 |

0.06 |

1.5 |

0.125 |

3.2 |

0.93 |

23.6 |

650 |

967 |

95 |

|

2×4 |

259 |

8 |

0.06 |

1.5 |

0.140 |

3.6 |

1.08 |

27.4 |

940 |

1399 |

127 |

|

2×2 |

259 |

6 |

0.06 |

1.5 |

0.155 |

3.9 |

1.27 |

32.3 |

1360 |

2023 |

167 |

|

2×1 |

259 |

5 |

0.08 |

2.0 |

0.170 |

4.3 |

1.44 |

36.6 |

1730 |

2574 |

191 |

|

2×1/0 |

259 |

4 |

0.08 |

2.0 |

0.170 |

4.3 |

1.52 |

38.6 |

2000 |

2976 |

217 |

|

2×2/0 |

259 |

3 |

0.08 |

2.0 |

0.170 |

4.3 |

1.65 |

41.9 |

2240 |

3333 |

250 |

|

2×3/0 |

259 |

2 |

0.08 |

2.0 |

0.190 |

4.8 |

1.77 |

45.0 |

2860 |

4255 |

286 |

|

2×4/0 |

259 |

1 |

0.08 |

2.0 |

0.190 |

4.8 |

1.92 |

48.8 |

3500 |

5207 |

328 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.