| Application and Description | 600 Volt EPR/XLPO Type RHH or RHW-2 or USE-2 is suited for use in mass transit and general industry applications where flexibility, fire resistance, and low smoke generation are concerns. May be installed in wet or dry locations (including direct burial for size AWG 8 and larger) in cable trays or in raceways. These cables are capable of operating continuously at a conductor temperature not in excess of 90°C for normal operation, 130°C for emergency overload conditions, and 250°C for circuit conditions. |

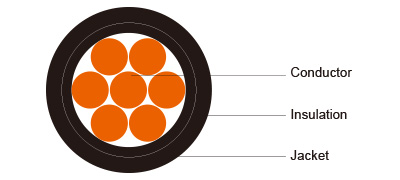

| Cable Construction | |

| Conductor | Class B compressed concentric stranded bare copper in accordance witd ASTM B3 and B8 and ICEA. |

| Insulation/Jacket | Being resistant to moisture, most oils, acids, and alkalies EPR (ethylene propylene rubber) insulation. Jacket: Flame retardant, moisture and sunlight resistant XLPO. |

| Color | upon request, black is preferable |

| Technical Characteristics | - UL 44 - Thermoset-Insulated Wires and Cables - UL 1581 - UL Flame Exposure Test (VW-1) - UL 1685 - UL Flame Exposure Test - ICEA S-68-516 (NEMA WC8) - RoHS |

Cable Parameter

|

AWG OR KCMIL |

STRAND |

NOMINAL INSULATION THICKNESS INCH/MM |

NOMINAL JACKET THICKNESS INCH/MM |

NOMINAL OVERALL DIAMETER INCH/MM |

CABLE WEIGHT LBS/KFT KG/KM |

||||

|

2 |

7 |

0.045 |

1.14 |

0.030 |

0.76 |

0.445 |

11.3 |

250 |

372 |

|

1 |

19 |

0.055 |

1.40 |

0.045 |

1.14 |

0.524 |

13.3 |

335 |

499 |

|

1/0 |

19 |

0.055 |

1.40 |

0.045 |

1.14 |

0.563 |

14.3 |

410 |

610 |

|

2/0 |

19 |

0.055 |

1.40 |

0.045 |

1.14 |

0.607 |

15.4 |

503 |

749 |

|

3/0 |

19 |

0.055 |

1.40 |

0.045 |

1.14 |

0.657 |

16.7 |

673 |

921 |

|

4/0 |

19 |

0.055 |

1.40 |

0.045 |

1.14 |

0.713 |

18.1 |

764 |

1137 |

|

250 |

37 |

0.065 |

1.65 |

0.065 |

1.65 |

0.838 |

21.3 |

940 |

1399 |

|

350 |

37 |

0.065 |

1.65 |

0.065 |

1.65 |

0.944 |

24.0 |

1274 |

1896 |

|

500 |

37 |

0.065 |

1.65 |

0.065 |

1.65 |

1.076 |

27.3 |

1769 |

2633 |

|

750 |

61 |

0.080 |

2.03 |

0.065 |

1.65 |

1.291 |

32.8 |

2616 |

3893 |

|

1000 |

61 |

0.080 |

2.03 |

0.065 |

1.65 |

1.445 |

36.7 |

3428 |

5101 |